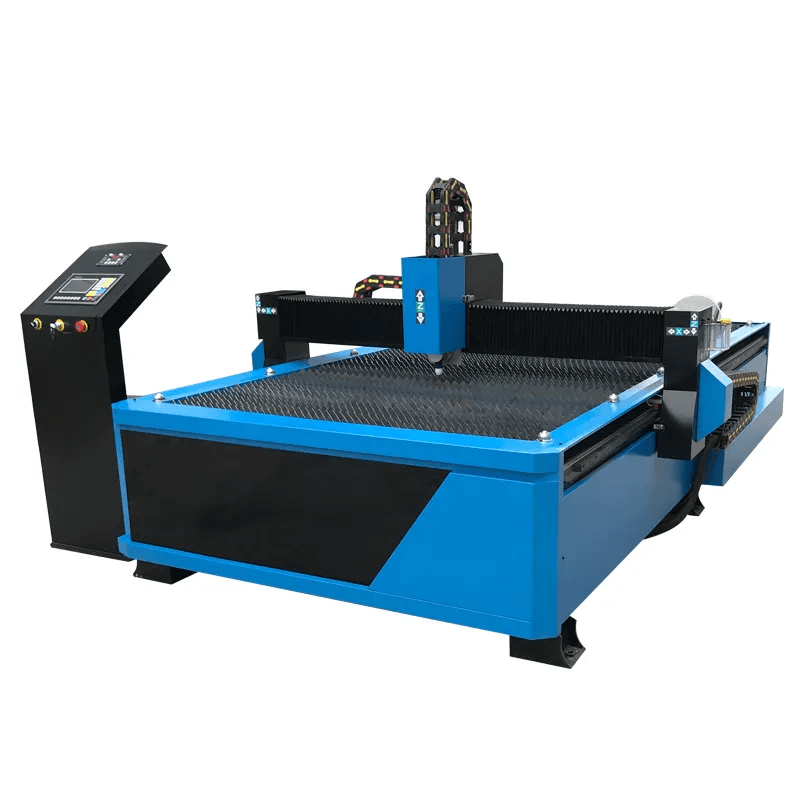

CNC Plasma Cutting Machine Manufacturer & Supplier

High Precision CNC Plasma Cutters for Metal Sheet & Pipe Cutting

Factory Direct Price | CE Certified | Worldwide Delivery

15+ Years CNC Experience

CE / ISO Certified

Exported to 80+ Countries

24/7 Technical Support

Our CNC Plasma Cutting Machine Models

Applications of CNC Plasma Cutting Machine

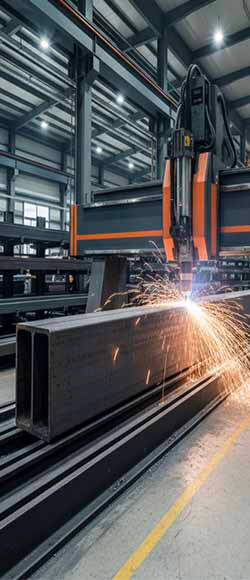

Steel Structure Fabrication

Sheet Metal Processing

Automotive Parts Manufacturing

HVAC and Duct Sheet Cutting

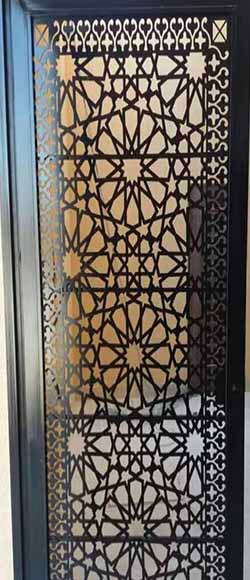

Advertising & Sign Making

Why Choose Our CNC Plasma Cutting Machines

343

Project Completed

6868

Support Done

12800

Secure Delivery

Partner Brands

Advanced Plasma Cutting Technology

High-quality Plasma Power Source

Automatic Torch Height Control (THC)

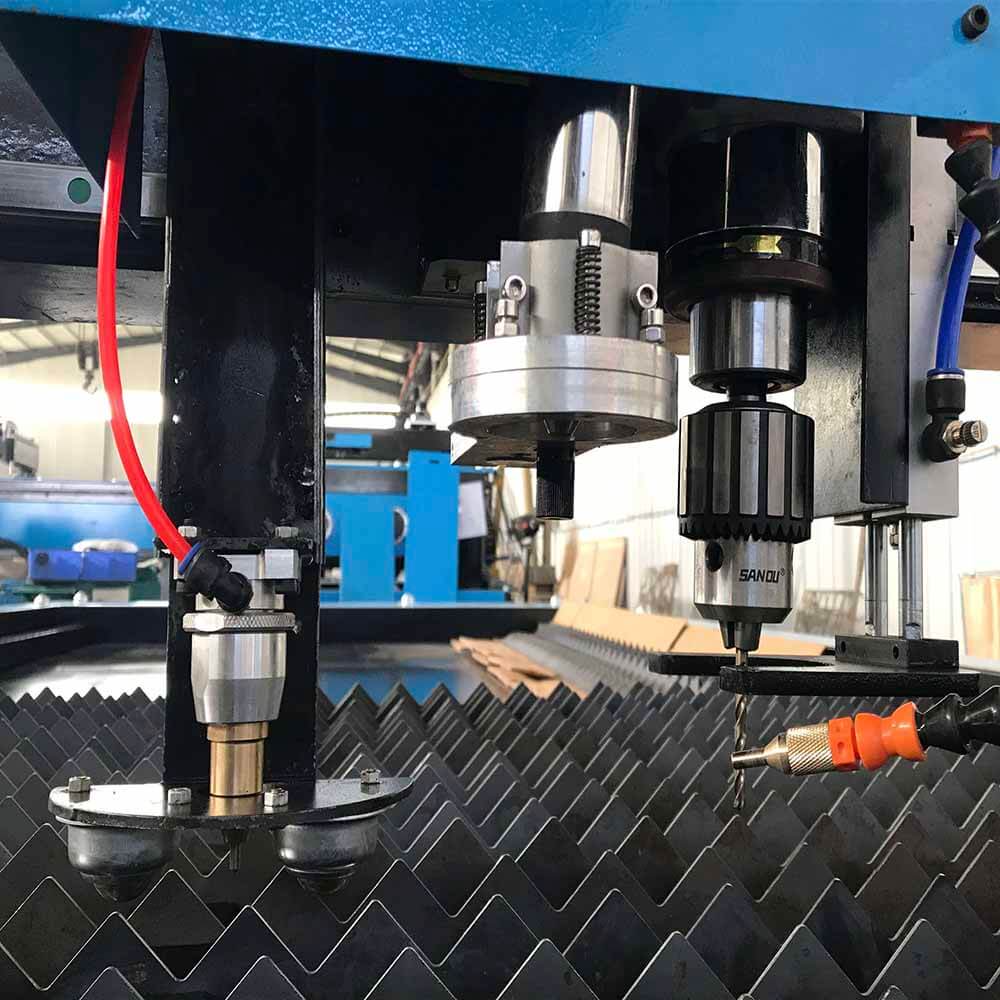

Multi Funtion Plasma Cutting Head

Heavy Strucutre & Precision Linear Guide

Trusted by Customers Worldwide

What Our Customers Say

Real feedback from global customers who use our CNC plasma cutting machines in daily production

CNC Plasma Cutting Machine FAQs

HappyAddons is a unique collection of Addons to power up the Elementor Page Builder plugin. It works with the WordPress and Elementor Page Builder to customize your WordPress blog or Business sites.

You will just need to have the latest version of Elementor installed on your website to be able to use the HappyAddons.

After the subscription license expires, HappyAddons Pro will stop working. Without the license key, you couldn’t use the pro features and widgets of HappyAddons. So you need to renew your license before it expires. That’s the way to prevent the site breaking issue.

And don’t worry, we will send you a reminder through email and admin notice banner of your WordPress dashboard.

You will find us whenever you need us. It’s truly 24/7! The annual license of the HappyAddons promises 1 year of support and updates from us. While the lifetime license makes sure we stand by you all way through.

The subscription involves recurrent payments.

The yearly subscription allows using the product included in it during one year from the date of purchase. When the year ends, the charges are taken to continue the subscription automatically.

If you’re using a Lifetime plan, the charges will be taken only once, and you’ll be able to use the product from the subscription and receive all the updates without any additional payments or charges taken.

Note: *Prices exclude VAT/Taxes

We built the HappyAddons to work wonders with the Hello Elementor Theme, we’re trying to make sure that it works great with all the major themes as well.

Looking for a Reliable CNC Plasma Cutting Machine?

Tell us your cutting material, thickness and working size.Our engineers will recommend the best solution for you.

Professional CNC Plasma Cutting Machine Supplier from China

As a professional CNC plasma cutting machine manufacturer and supplier from China, we focus on designing and producing reliable CNC plasma cutting machines for global metal fabrication industries. Our CNC plasma cutters are engineered for high cutting accuracy, fast speed, and stable performance, suitable for cutting carbon steel, stainless steel, aluminum, and other metal materials.

With years of manufacturing experience, we offer a complete range of CNC plasma cutting machine solutions, including standard models, heavy-duty CNC plasma cutters, and customized plasma cutting systems based on different working sizes, cutting thicknesses, and application requirements. Each CNC plasma cutting machine is manufactured under strict quality control standards and fully tested before shipment.

We have successfully exported CNC plasma cutting machines to customers in North America, Europe, South America, the Middle East, and Southeast Asia. To ensure a smooth purchasing experience, we provide professional export packaging, clear technical documentation, and efficient global logistics support.

Our after-sales service includes online installation guidance, machine operation training, troubleshooting assistance, and long-term technical support. We are committed to delivering high-quality CNC plasma cutting machines and reliable service to help customers improve productivity and reduce operating costs.