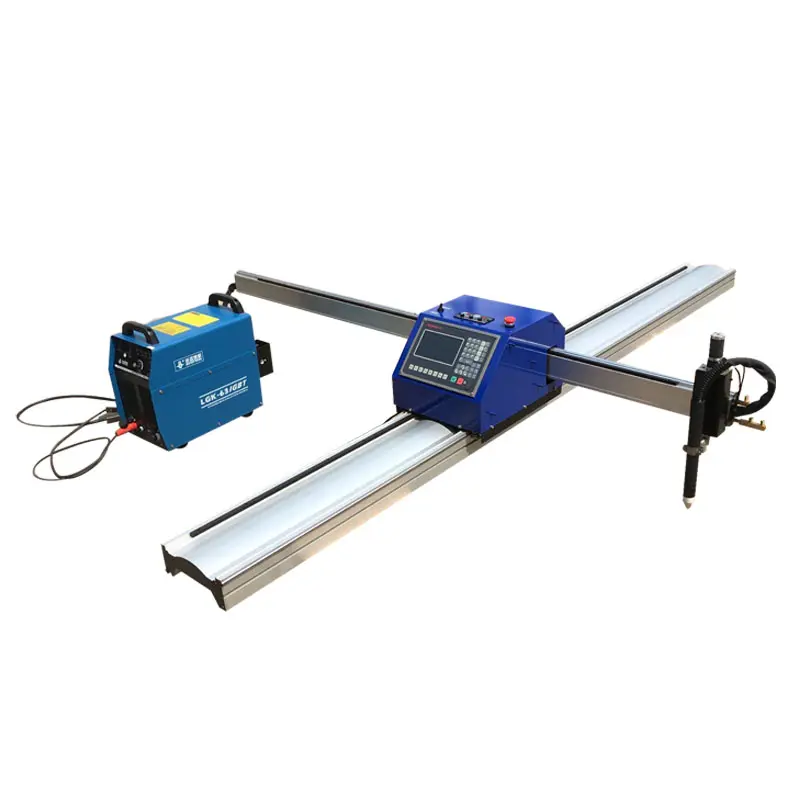

2025 Top Rated CP-1530 Portable CNC Plasma Cutting Machine

- Model: CP-1530

- Working Size: 1500*3000mm

- Plasma Source: 120A (Optional 63/100/160/200/300/400A)

- Cutting Thickness: 1-20mm

- Availability: Production after order confirmation (Preorder)

- Payment Method: Bank Transfer (T/T), Trade Assurance

- Standard - Meeting CE Standards in Terms of Quality & Safety

- Warranting - One (1) Year Limited Warranty for Entire Machine

The portable CNC plasma flame cutting machine offers dual cutting capabilities: plasma cutting and oxy-fuel (flame) cutting. Plasma mode is typically used for cutting metals with a thickness of up to 30mm, making it ideal for light to medium-duty tasks. For heavier applications, the flame cutting mode is suitable for cutting steel or iron plates ranging from 30mm to 200mm in thickness.

Features of 2025 Top Rated CP-1530 Portable CNC Plasma Cutting Machine

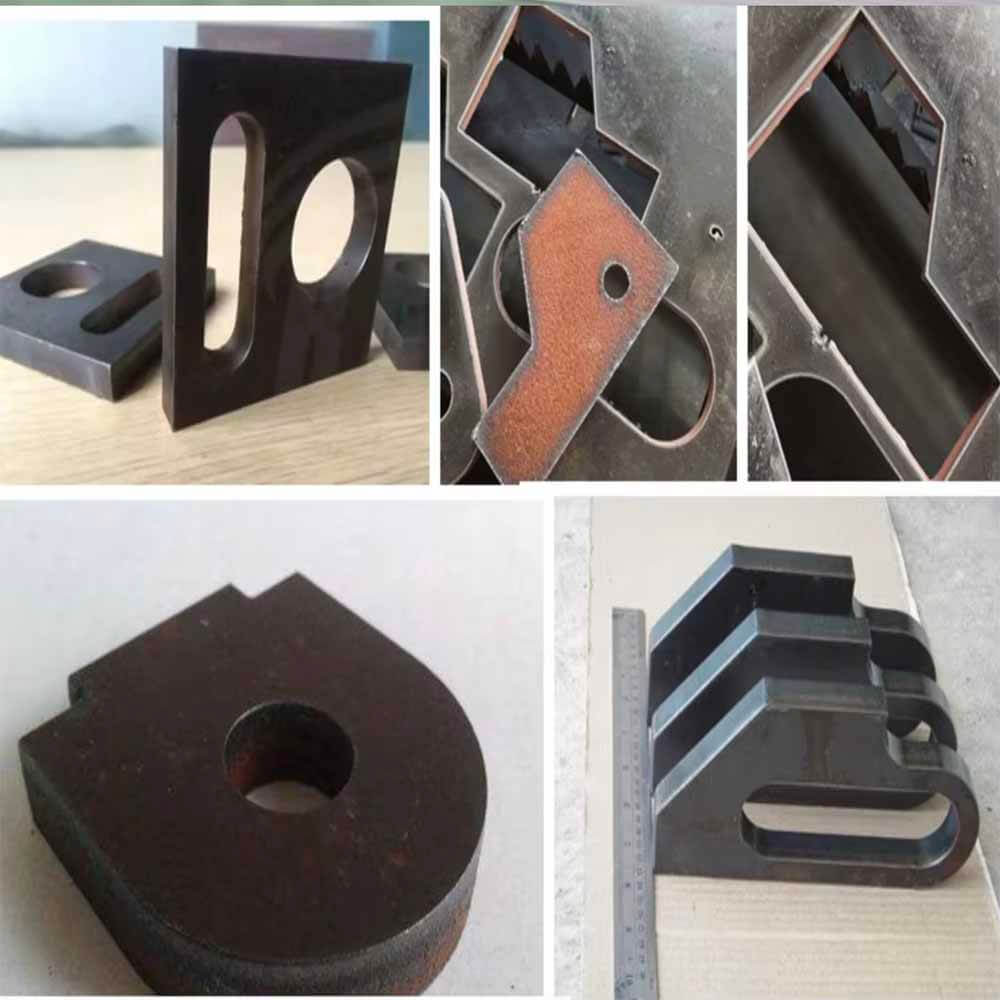

- Equipped with the StartShaphon CNC control system, this machine is capable of cutting any complex flat metal shape with high efficiency and low operating cost, making it ideal for diverse industrial applications.

- The integrated nesting software directly supports AutoCAD drawing file import, converting DXF formats into executable cutting paths. Its intuitive interface and automated programming capabilities ensure ease of use and high productivity.

- Fitted with the SF25G automatic torch height controller, the cutting torch can automatically maintain optimal cutting distance, ensuring precise and consistent results across the entire workpiece.

- Designed with a compact frame, modern appearance, lightweight construction, and easy mobility, the machine supports both manual operation and automated cutting modes, delivering smooth movement and excellent cutting precision.

- Built with a telescopic boom-type gantry, both the X and Y axes use aviation-grade aluminum alloy, ensuring high positioning accuracy, structural stability, and a sleek design with no deformation over time.

- Standard Models: A1525: 1500mm x 2500mm/B1530: 1500mm x 3000mm

Custom Sizes Available: 1500mm x 4000/6000/8000/10000/12000mm to suit various cutting needs. - Material Compatibility: Suitable for cutting iron plates, mild steel, galvanized steel, stainless steel, titanium, and aluminum sheets.

- Industries Served: Widely applied in shipbuilding, ventilation ducts, heating stove manufacturing, automotive parts, agricultural machinery, metal plate processing, pressure vessels, steel towers, railway, and aerospace industries.

Specification of 2025 Top Rated CP-1530 Portable CNC Plasma Cutting Machine

| Item | Specification (Rewritten) |

|---|---|

| Model Number | CP-1530 CNC Plasma Cutting System |

| Input Voltage | AC 220V / 380V, 50Hz (single or three-phase configurable) |

| Effective Cutting Area | 1500mm x 3000mm (5ft x 10ft cutting platform) |

| Plasma Cutting Capacity | 0–30mm (depending on the plasma source model and power rating) |

| Oxy-fuel Cutting Range | 1–200mm (flame cutting thickness for steel and other materials) |

| Machine Net Weight | Approx. 230 kg |

| Control Panel | STARFIRE CNC Controller (FANGLING optional as upgrade) |

| Drive Motor System | LEADSHINE hybrid stepper motor drive |

| Motion Transmission | High-precision gear rack drive system |

| Plasma Power Supply | Compatible with HUAYUAN or Hypertherm plasma generators |

| Linear Motion Guide | Precision round guide rail system |

| Nesting & Programming | Includes FASTCAM software for layout and automatic nesting |

Application of 2025 Top Rated CP-1530 Portable CNC Plasma Cutting Machine

This machine is capable of cutting mild steel using flame cutting, and is also suitable for cutting high carbon steel, stainless steel, aluminum, copper, and other non-ferrous metals using plasma cutting technology. It can be customized according to specific customer needs, making it highly versatile and widely used across various industries such as machinery manufacturing, automotive production, shipbuilding, petrochemical engineering, defense, metallurgy, aerospace, boiler fabrication, pressure vessel manufacturing, and railway equipment.

It is especially well-suited for metal sheet processing and is also compatible with advertising-related machinery like vacuum forming machines, engraving machines, and slotting machines, helping form a complete automated advertising sign production line. Compared to traditional manual methods, this machine significantly increases productivity—offering efficiency gains of dozens of times over conventional processing techniques.