CNC Plasma Cutting Machines for Sale – Precision Metal Cutting Solutions in the UK

Whether you’re based in the UK or serving clients across Europe, investing in a quality CNC plasma cutting machine UK supplier offers access to advanced technology, responsive support, and trusted performance. These machines are designed to streamline your metal cutting processes—whether you’re cutting thin sheet metal or thick industrial steel.

Table of Contents

What is a CNC Plasma Metal Cutting Machine?

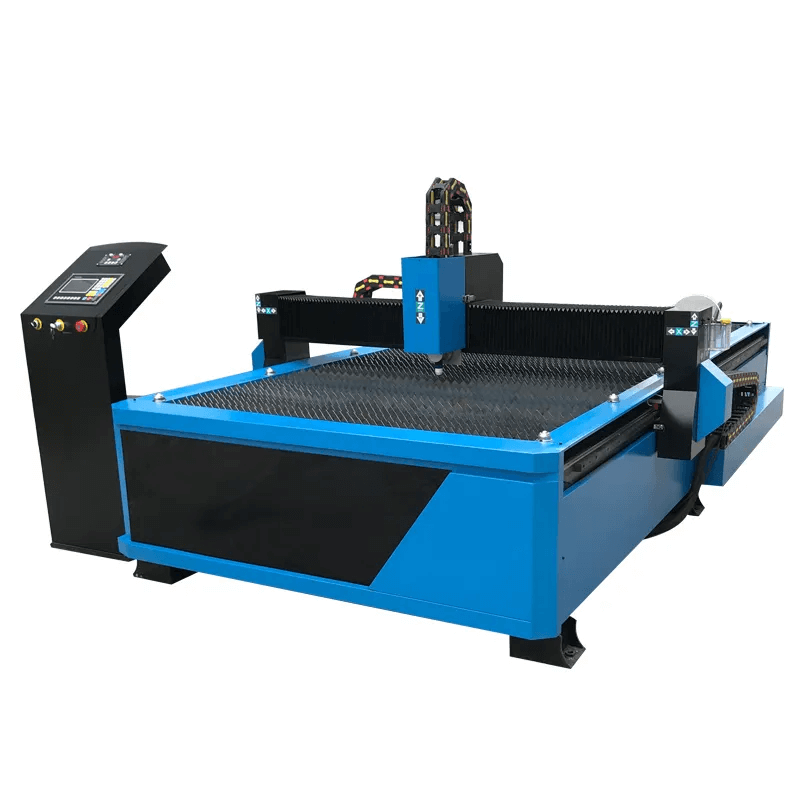

A CNC plasma metal cutting machine is a computer-controlled system that uses a high-temperature plasma arc to cut conductive metals like mild steel, stainless steel, and aluminum. The CNC controller automates movement, cut paths, and torch settings, ensuring repeatable accuracy and reduced human error.

These machines are used across industries such as:

- Sheet metal fabrication

- Structural steel work

- HVAC manufacturing

- Automotive and shipbuilding

- Agricultural machinery production

CNC Plasma Cutting Machine UK: Why Buy Locally?

If you’re located in the UK, choosing a CNC plasma cutting machine UK supplier offers several advantages:

- Fast delivery and local service support

- Custom configurations for UK power and safety standards

- Access to local consumables and spare parts

- Reliable training and technical assistance

Buying locally also means easier warranty management and peace of mind when it comes to machine servicing or upgrades.

Plasma vs Oxy-Fuel: Choose the Right CNC Cutter

Many workshops benefit from machines that combine plasma and flame cutting. A CNC plasma oxy fuel cutting machine provides the flexibility to handle both thin and thick materials with ease.

Plasma Cutting:

- Ideal for thin to medium-thickness metals (1–30mm)

- Clean, fast cuts with minimal heat distortion

- Works on stainless steel, aluminum, and carbon steel

Oxy-Fuel Cutting:

- Best suited for very thick carbon steel (above 30mm)

- Lower initial cost and great for heavy-duty fabrication

- Not suitable for non-ferrous metals

A dual-process CNC plasma oxy fuel cutting machine allows you to switch between torch types depending on your material and job requirements, offering maximum versatility in one compact system.

Features to Look for in a CNC Plasma Cutter

When browsing for a CNC plasma cutting machine for sale, consider the following features:

- Working size: Match the table size to your material dimensions (e.g., 1500x3000mm)

- Power source: Choose trusted brands like Hypertherm or Huayuan

- Controller: User-friendly interface with advanced nesting and G-code support

- THC (Torch Height Control): Ensures consistent cutting even on warped sheets

- Rotary attachment (optional): For cutting pipes and tubes

CP-1530 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CT-1530 |

| Machine Type | CNC Plasma & Flame Cutting Machine |

| Cutting Method | Plasma Cutting & Oxy-Fuel (Flame) Cutting |

| Working Area (X × Y) | 1500mm × 3000mm |

| Effective Cutting Width (X-Axis) | 1500mm |

| Effective Cutting Length (Y-Axis) | 3000mm |

| Cutting Thickness (Plasma) | 1–25mm (depending on plasma power source) |

| Cutting Thickness (Flame) | 6–100mm (customizable torch available for thicker cuts) |

| Cutting Speed | Plasma: 0–8000 mm/min Flame: 0–600 mm/min |

| Positioning Accuracy | ±0.3mm |

| Repositioning Accuracy | ±0.2mm |

| Drive System | Stepper Motor with Dual Side Rack and Pinion Drive |

| Control System | FLMC-F2300A / Starfire / Fangling CNC Controller |

| Software Compatibility | FASTCAM, AutoCAD, G Code |

| Input File Format | G Code / .nc / .txt / .dxf |

| Plasma Power Supply | Optional: Huayuan / Hypertherm (63A / 100A / 120A / 200A) |

| Flame Cutting Torch | Manual or Automatic Ignition Oxy-Fuel Torch |

| Torch Height Control (THC) | Automatic THC for Plasma; Manual for Flame |

| Gas Supply for Flame Cutting | Acetylene or Propane + Oxygen |

| Working Voltage | AC 220V/380V ±10%, 50/60Hz |

| Table Type | Blade Table (Optional Water Table Available) |

| Machine Frame | Heavy-duty Welded Steel Structure |

| Optional Features | – Rotary Axis for Pipe Cutting – Dust Collector – Water Table |

| Net Weight | Approx. 1000–1200 kg |

| Overall Dimensions (L×W×H) | Approx. 2200 × 3800 × 1600 mm |

Conclusion

Whether you need a compact table for light fabrication or a heavy-duty CNC plasma oxy fuel cutting machine for thick industrial steel, there’s a solution for every workshop. If you’re looking for a reliable CNC plasma cutting machine for sale, be sure to consider options available in the UK for local support and fast lead times.

A high-performance CNC plasma metal cutting machine can transform your productivity and cutting quality—bringing speed, precision, and efficiency to every job.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution