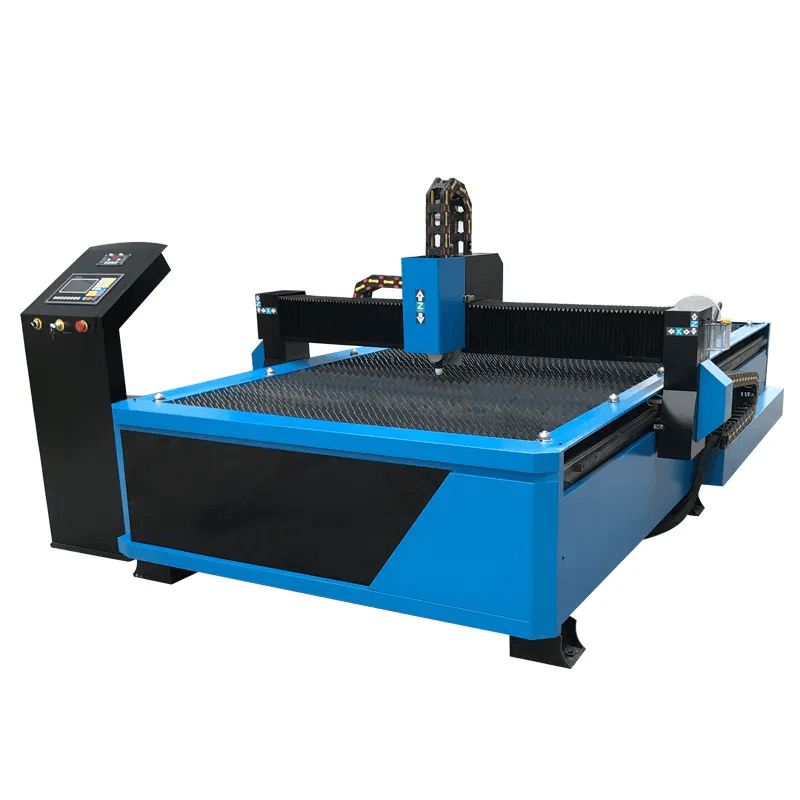

Plasma CNC Cutting Machines: Portable, Precise, and Affordable

Whether you’re working in a fabrication shop, construction site, or metalworking studio, a portable CNC plasma cutting machine delivers excellent performance without compromising on mobility or precision.

Table of Contents

Why Choose a Plasma Cutter Machine at Factory Price?

Buying directly from a factory gives you several key advantages:

- Cost Savings: Eliminates middleman markups.

- Customization Options: Machines tailored to your specific needs.

- Direct Support: Faster after-sales service and training.

- Upgraded Components: Latest technology in torch height control, plasma power supply, and software.

Key Features of Plasma CNC Cutting Machines

| Feature | Details |

|---|---|

| Cutting Material | Mild steel, stainless steel, aluminum, etc. |

| Cutting Method | Plasma or oxy-fuel optional |

| Control System | Starfire, FLMC-2300A, or upgraded options |

| Software Compatibility | FASTCAM, AutoCAD, G Code |

| Portability | Lightweight frame, ideal for field jobs |

| Precision | High repeatability accuracy (±0.2mm) |

| Power Source | Supports Hypertherm or Chinese plasma power |

| Applications | Sheet metal fabrication, auto parts, ducting |

Who Should Consider Plasma CNC Cutting Machines?

These machines are ideal for:

- Fabrication workshops

- HVAC companies

- Metal art studios

- Industrial manufacturing

- Auto and machine part production

Whether you’re a start-up or scaling your business, a plasma CNC cutting machine like the 1560 portable model offers the perfect mix of affordability and functionality.

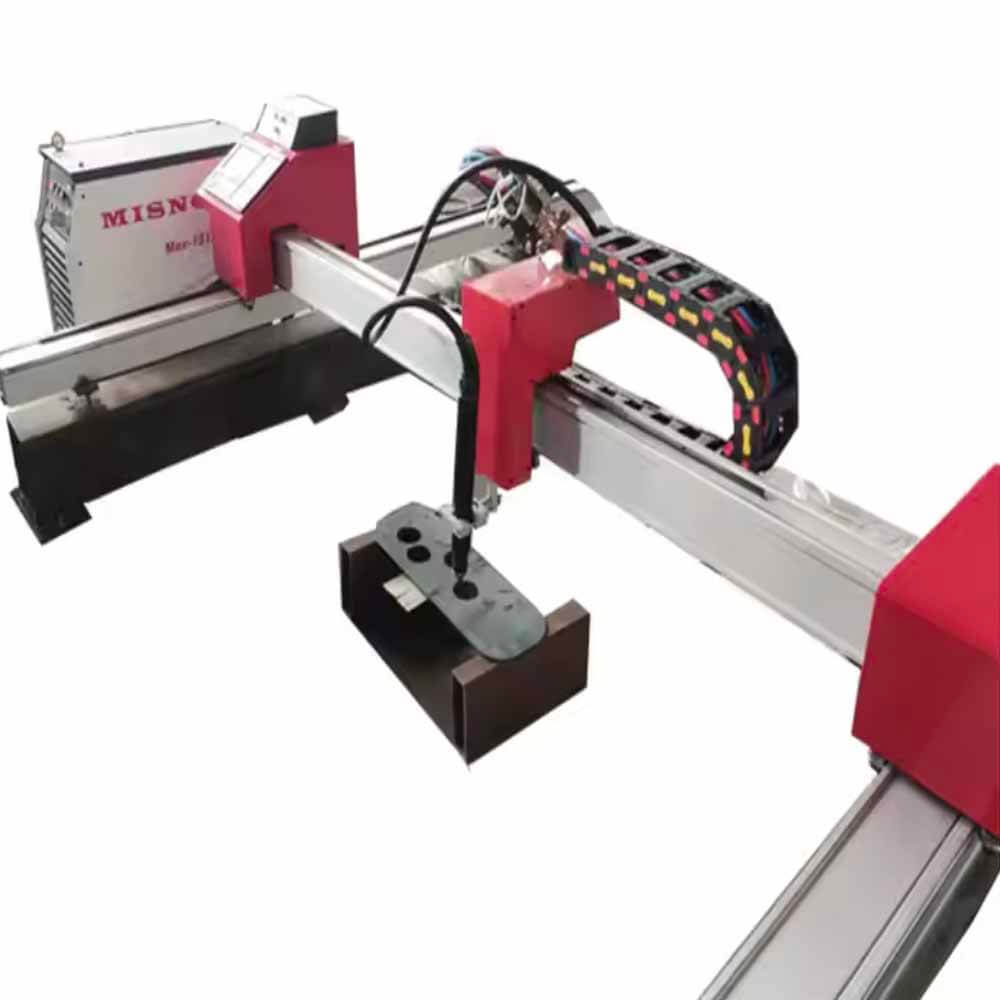

Technical Specifications

| Model | CP-1560 Portable CNC Plasma Cutter |

|---|---|

| Cutting Method | Plasma (optional Oxy-fuel cutting available) |

| Working Area (X*Y) | 1500mm x 6000mm |

| Machine Type | Portable Gantry CNC Plasma Cutting Machine |

| Control System | STARFIRE / FLMC-2300A / Fangling CNC Controller |

| Motor & Drive | Stepper motor + leadshine drivers (Servo optional) |

| Guide Rail Type | Linear guide rails |

| Transmission | Precision rack and pinion |

| Cutting Speed | 0–8000 mm/min |

| Positioning Accuracy | ±0.2mm |

| Cutting Thickness | Plasma: 1–25mm (depends on plasma source) |

| Plasma Power Source | Optional: Huayuan / Hypertherm (63A / 100A / 120A) |

| Power Supply Voltage | AC220V/380V, 50/60Hz |

| Software Compatibility | FastCAM / StarCAM / AutoCAD supported |

| File Transfer Method | USB, U-disk |

| Gas Type | Air / O2 / N2 / Mixed gas |

| Height Control System | Automatic Arc Voltage Torch Height Controller |

| Working Environment | 0–45°C, Humidity < 90% |

| Machine Weight | Approx. 300–500 kg (depends on configuration) |

| Optional Features | Flame cutting head, Rotary axis, Dust collector |

| Application | Sheet metal cutting, HVAC, auto parts, steel art |

Conclusion

Investing in a Plasma Cutter Machine at Factory Price is a smart move for anyone serious about cutting quality and cost-efficiency. From the CNC Portable Plasma Cutter 1560 to other customizable models, these machines deliver the power, precision, and portability that modern metalworking demands.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution