Powerful and Portable Solutions for Cutting Metal and Aluminium Plates

Whether you’re working in a factory, workshop, or on-site, having a metal plate cutting machine or aluminium plate cutting machine that delivers clean cuts and consistent performance is essential. For those needing mobility and flexibility, a portable plasma cutting machine is the ideal solution.

Table of Contents

What is a Metal Plate Cutting Machine?

A metal plate cutting machine is designed to handle a wide range of ferrous and non-ferrous materials. From mild steel to stainless steel, these machines deliver precise, high-speed cuts using advanced CNC or manual control. Common types include plasma cutters, flame cutters, and laser machines.

Key Benefits:

- Cuts thick and thin metal sheets with accuracy

- High-speed production suitable for large batches

- Compatible with CAD/CAM software

- Suitable for industrial and commercial fabrication

Special Consideration for Aluminium Plate Cutting

Aluminium plate cutting machines are optimized for the unique properties of aluminum, which requires careful heat management to avoid warping or rough edges. Plasma cutters are especially effective for cutting aluminum due to their fast and contactless operation.

Features of Aluminium Plate Cutting Machines:

- Clean, burr-free cuts

- Minimal heat-affected zones

- Advanced torch height control systems

- Precision cutting for decorative and structural components

Why Choose a Portable Plasma Cutting Machine?

A portable plasma cutting machine combines the power of high-frequency plasma cutting with the convenience of mobility. It’s perfect for field jobs, small workshops, or any scenario where space and flexibility are limited.

Advantages of Portable Plasma Cutters:

- Lightweight and easy to transport

- No compromise on cutting depth or quality

- Cost-effective for smaller projects

- Ideal for maintenance, repair, and installation work

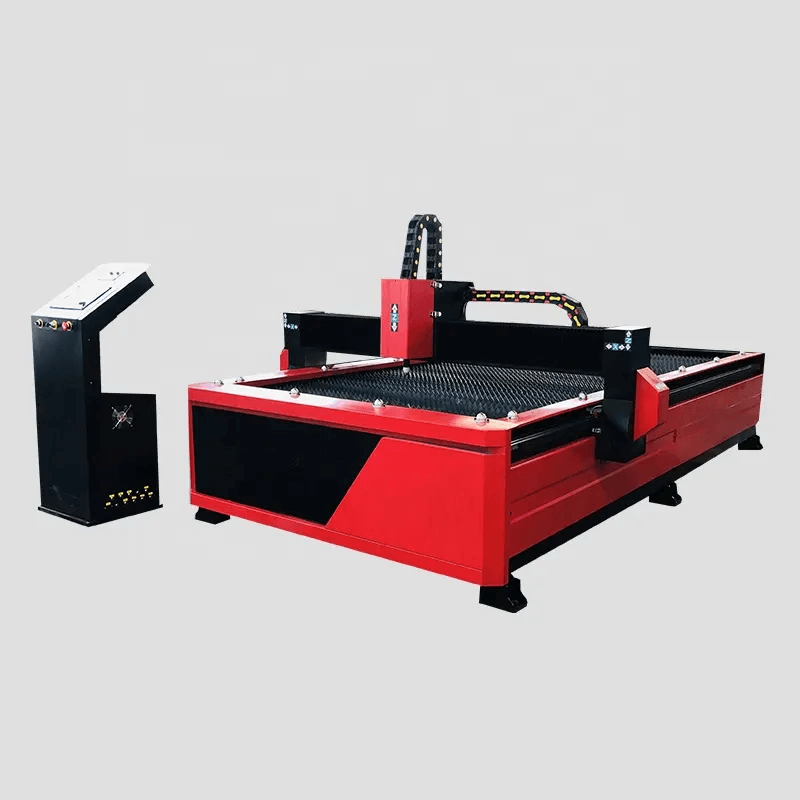

CP-1540 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-1540 |

| Machine Type | CNC Plasma Cutting Machine |

| Working Area (X × Y) | 1500mm × 4000mm |

| Cutting Mode | Plasma Cutting (Optional: Oxy-Fuel) |

| Control System | STARFIRE / FLMC / START / other CNC Controller (as per need) |

| Plasma Power Source | Optional: Hypertherm / Huayuan / LGK / Thermal Dynamics |

| Cutting Thickness | Plasma: 1-25mm (depending on power source) |

| Oxy-Fuel Cutting Thickness | 5-100mm |

| Cutting Speed | 0–8000 mm/min |

| Positioning Accuracy | ±0.05 mm |

| Drive System | Stepper / Servo Motor with Dual Drive on Y-axis |

| Transmission System | Gear and Rack Drive + Linear Guides |

| Work Table | Steel Plate Support / Blade or Sawtooth Design |

| Table Structure | Integrated Welding Frame |

| Height Control | Automatic Arc Voltage Height Controller (AVHC) |

| Power Supply Voltage | AC 220V/380V, 50/60Hz (Customized Available) |

| Software Compatibility | FastCAM / StarCAM / AutoCAD (DXF, G-code) |

| Supported File Formats | G-code, DXF, etc. |

| Machine Dimensions (L×W×H) | Approx. 2300 × 4800 × 1600 mm |

| Gross Weight | Around 1500 kg |

| Optional Accessories | Flame torch, Fume Extractor, Water Table, Rotary Axis |

| Applications | Mild Steel, Stainless Steel, Aluminum, Galvanized Sheet |

Conclusion

Investing in the right cutting technology can significantly boost your productivity and cutting accuracy. Whether you need a stationary metal plate cutting machine, a specialized aluminium plate cutting machine, or a portable plasma cutting machine for on-the-go projects, there’s a solution that fits your needs. With robust design and cutting-edge features, these machines are essential tools for modern metalworking professionals.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution