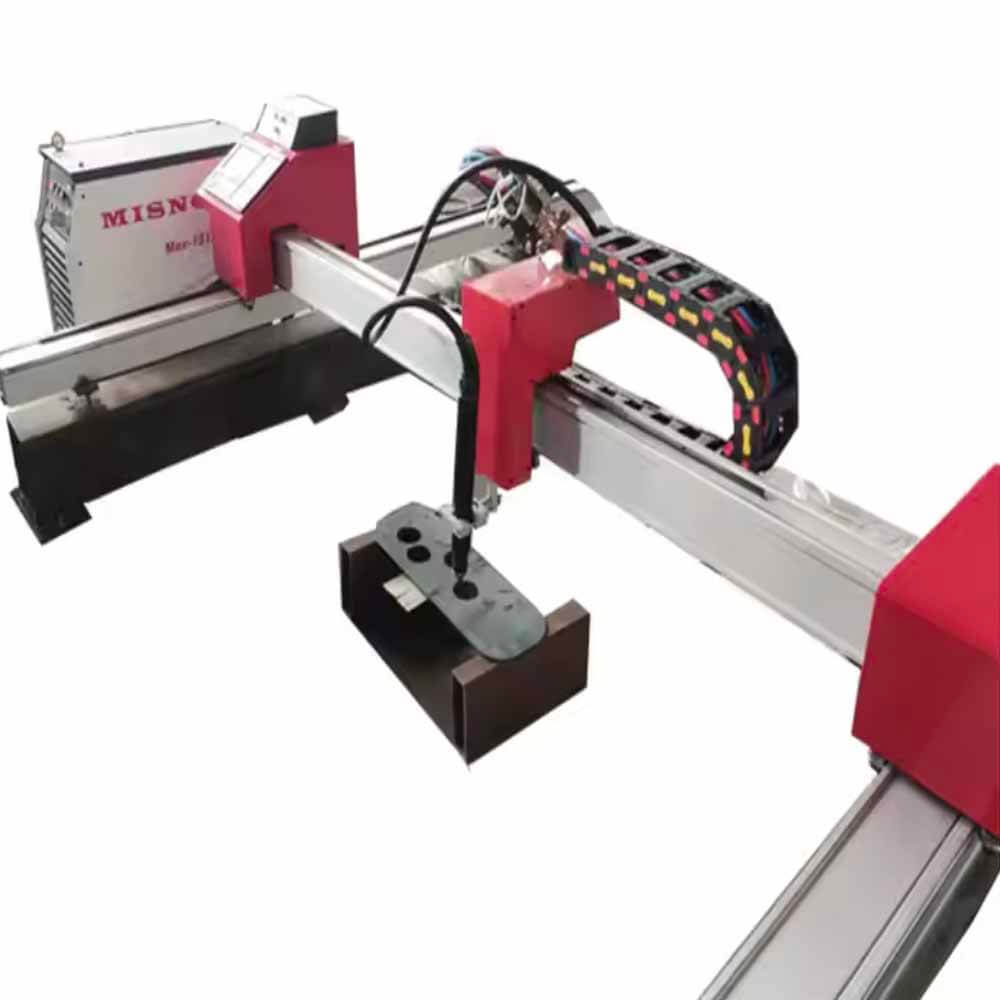

Mini CNC Plasma Cutting Machine: Compact Power for Precision Cutting

These compact machines deliver powerful performance, high precision, and portability—all at a cost-effective price. Whether you need a portable CNC plasma system or a cutting plasma CNC mini setup for small parts and light industrial use, this article will guide you through the advantages and applications of these versatile machines.

Table of Contents

What is a Mini CNC Plasma Cutting Machine?

A mini CNC plasma cutting machine is a compact, computer-controlled system that uses plasma torch technology to cut conductive materials such as steel, aluminum, brass, and copper. It is engineered for small work areas while maintaining the accuracy and features of larger CNC plasma cutting machines. These machines often come with a working size of 600x900mm or 1000x1500mm, making them ideal for detailed jobs or tight spaces.

Key Features of a Mini CNC Plasma Cutter

- Compact Design: Small footprint fits easily into workshops or garage setups.

- High Precision: Offers excellent cut quality for thin to medium-thickness materials.

- Portability: Lightweight and easy to transport—perfect for on-site work.

- User-Friendly Interface: Intuitive control systems for beginners and pros alike.

- Compatibility: Supports industry-standard file formats like DXF and G-code.

Advantages of a Portable CNC Plasma Machine

- Space-Saving Efficiency: A portable CNC plasma cutting machine is perfect for limited workspaces or mobile operations.

- Cost-Effective Investment: Lower upfront cost compared to large industrial machines, while still capable of professional results.

- Flexible Applications: Can cut various metals and shapes for signage, brackets, custom parts, art, and automotive repairs.

- Quick Setup: Minimal assembly required; just plug in, configure, and start cutting.

CP-1325 CNC Plasma Cutter Specification

| Model | CP-1325 CNC Plasma Cutter |

|---|---|

| Working Area (X*Y) | 1300mm x 2500mm |

| Cutting Method | Plasma Cutting (Optional Flame Cutting) |

| Plasma Power Source | 63A / 100A / 120A / 160A / 200A (Optional: Huayuan or Hypertherm) |

| Power Supply | 380V/50Hz/3Phase (Can be customized) |

| Torch Height Control | Automatic THC + Arc Voltage Control |

| Cutting Thickness | 0.5 – 25mm (Depending on power source) |

| Cutting Speed | 0 – 8000 mm/min |

| Drive System | Stepper / Servo Motor (Optional) |

| Control System | Starfire / FL / Fangling CNC Controller |

| Transmission | X,Y Gear Rack; Z Ball Screw |

| Rail Type | Linear Square Guide Rail |

| Table Type | Steel Blade Table / Water Table (Optional) |

| Software Compatibility | FastCAM / StarCAM / AutoCAD compatible |

| File Format | G-code, DXF, etc. |

| Working Gas | Air / Oxygen / Nitrogen |

| Positioning Accuracy | ±0.05mm |

| Machine Frame | Welded Steel Tube Structure |

| Optional Features | Flame Cutting Torch, Marking System, Rotary Device |

Choosing the Right CNC Plasma Cutter

When selecting a mini CNC plasma cutting machine, consider:

- Cutting thickness requirements

- Type of plasma power source (e.g., Huayuan, Hypertherm)

- Control system (Starfire, Start, FLMC)

- Table size and portability features

- Availability of after-sales support from the supplier

Look for a trusted CNC plasma cutting machine manufacturer that offers reliable machines, training resources, and technical support.

Conclusion

The mini CNC plasma cutting machine is a game-changer for small-scale metal cutting. Combining precision, portability, and affordability, it offers the perfect solution for craftsmen and businesses with limited space or budget. If you’re looking for a portable CNC plasma solution that doesn’t compromise on quality, a cutting plasma CNC mini machine might be exactly what you need.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution