Affordable 5×10 CNC Plasma Pipe Cutting Machine for Sale

- Model: CP-1530-TUBE

- Working Size: 1500*3000mm

- Plasma Source: 120A (Optional 63/100/160/200/300/400A)

- Rotary Device: 100-600mm

- Availability: Production after order confirmation (Preorder)

- Payment Method: Bank Transfer (T/T), Trade Assurance

- Standard - Meeting CE Standards in Terms of Quality & Safety

- Warranting - One (1) Year Limited Warranty for Entire Machine

ChatGPT said:

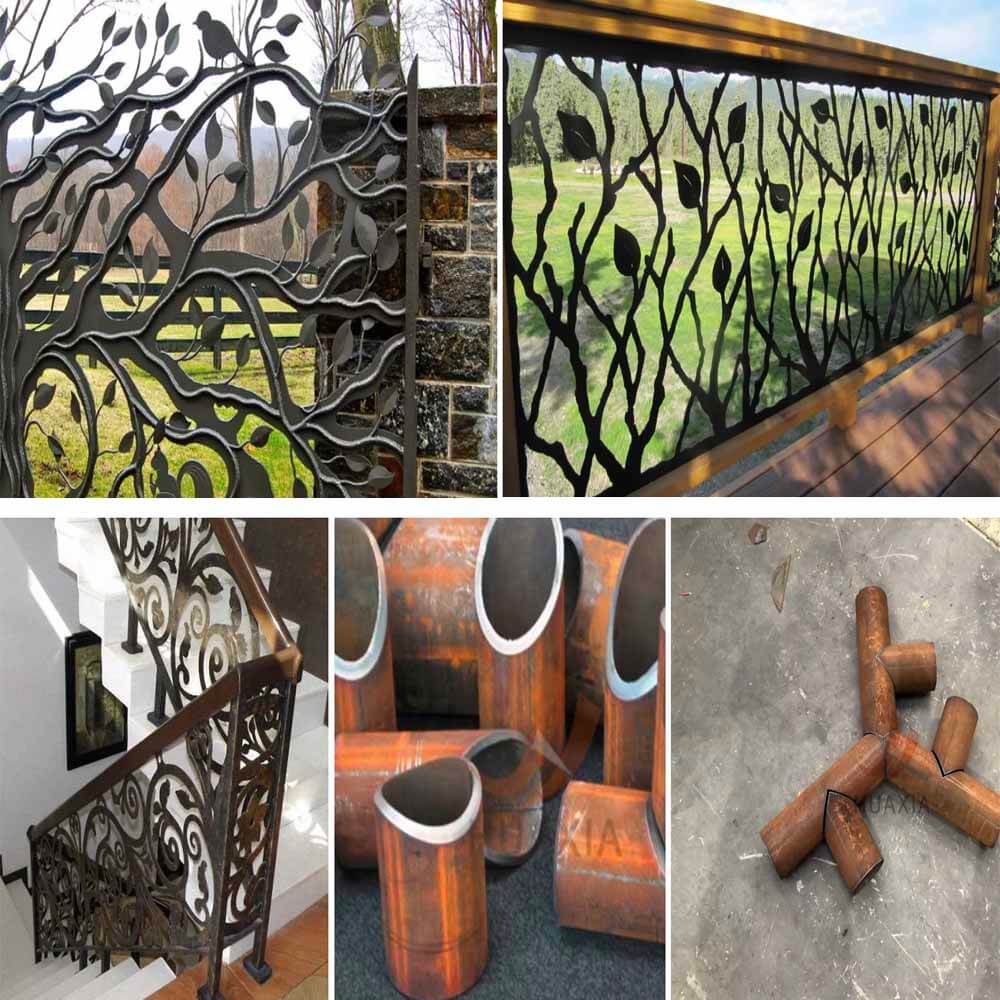

The Affordable 5×10 CNC Plasma Pipe Cutting Machine is a versatile and budget-friendly solution for cutting both sheet metal and pipes. With a 1500×3000mm working area and an integrated rotary axis, it handles flat plates and round, square, or rectangular tubes with precision. Ideal for fabrication shops, construction, and custom metalwork, it cuts carbon steel, stainless steel, and aluminum efficiently. Featuring a sturdy frame, automatic torch height control, and easy-to-use CNC systems like STARfire or FSCUT, this machine delivers reliable performance and excellent value for small to mid-sized businesses.

Features of Affordable 5×10 CNC Plasma Pipe Cutting Machine for Sale

- Dual Function Cutting – Supports both flat sheet cutting (5×10 ft) and pipe/tube cutting, making it ideal for versatile metal fabrication needs.

- Robust Machine Frame – Built with a heavy-duty welded steel structure for long-term stability, reduced vibration, and precise performance during high-speed cutting.

- Automatic Torch Height Control (THC) – Ensures consistent arc distance on uneven surfaces, resulting in smoother cuts and extended consumable life.

- Rotary Axis for Pipe Cutting – Integrated rotary device accommodates round, square, and rectangular tubes, perfect for custom pipe cutting projects.

- High Cutting Precision – Delivers accurate cuts with a positioning tolerance as low as ±0.05mm, suitable for both industrial and workshop environments.

- Powerful Plasma Source Options – Compatible with various plasma power supplies such as HUAYUAN or Hypertherm for cutting different thicknesses of carbon steel, stainless steel, and aluminum.

- User-Friendly CNC Controller – Equipped with intuitive control systems like STARfire or FSCUT, supporting G-code and DXF file formats for easy operation and fast programming.

- Affordable and Efficient – Designed to offer high performance at a budget-friendly price, making it an excellent choice for small businesses, metal workshops, and fabrication startups.

Specification of Affordable 5×10 CNC Plasma Pipe Cutting Machine for Sale

| Item | Specification |

|---|---|

| Model | CP-1530-TUBE |

| Working Area (Sheet Cutting) | 3000 × 1500 mm |

| Tube Cutting Capacity | Ø16–Ø220 mm (round tube), length ≤6000 mmDiagonal ≤200 mm (square/rectangular) |

| X-Axis Travel | 2350 mm |

| Y-Axis Travel | 3050 mm |

| Z-Axis Travel | 240 mm |

| Positioning Accuracy (X, Y) | ±0.05 mm per 1000 mm |

| Repeat Positioning Accuracy | ±0.03 mm per 1000 mm |

| Acceleration | 1G |

| Maximum Running Speed | 80 m/min |

| Rear Chuck Max. Rotation Speed | 100 rpm |

| Minimum Tailing Length | ≥90 mm (varies with tube type) |

| Maximum Table Load | 900 kg |

| Machine Dimensions | 7600 × 3500 × 1700 mm (including rotary axis) |

| Laser Power | 3000 W |

| Control System | FSCUT |

| Total Installed Power | 19 kW |

| Power Supply Voltage | 380V, 50Hz |

Application of Affordable 5×10 CNC Plasma Pipe Cutting Machine for Sale

The Affordable 5×10 CNC Plasma Pipe Cutting Machine is a versatile solution designed for cutting both metal sheets and pipes with high precision and efficiency. With a flat cutting area of 1500×3000mm (5×10 feet) and an integrated rotary axis for pipe and tube processing, this machine is widely used across industries such as metal fabrication, construction, automotive, HVAC, agricultural machinery, and custom steel structure production. It is capable of cutting carbon steel, stainless steel, aluminum, and galvanized pipes—making it ideal for producing handrails, support structures, steel frames, brackets, and exhaust systems. This dual-purpose CNC plasma cutter simplifies complex workflows, reduces labor costs, and significantly improves production speed, making it a cost-effective choice for small workshops, fabrication businesses, and industrial manufacturers looking to handle both plate and tube cutting in one compact machine.