CNC Plasma and Oxy Fuel Cutting Machines from a Trusted China Manufacturer

These machines provide accurate, efficient, and high-speed cutting for a wide range of materials, including mild steel, stainless steel, and aluminum. If you’re looking to boost your production quality and throughput, investing in a reliable cutting solution is critical.

Table of Contents

Why Choose CNC Plasma and Oxy Fuel Cutting Machines?

CNC plasma cutting uses an electrically conductive gas to create a high-temperature plasma arc that melts through metal with extreme precision. On the other hand, oxy fuel cutting relies on a chemical reaction between oxygen and fuel gas to cut thicker materials with ease. Combining these technologies into one system provides unmatched versatility for manufacturers handling diverse cutting tasks.

These machines are ideal for:

- Steel fabrication

- Heavy machinery production

- Shipbuilding

- HVAC ductwork

- Custom metal art and signage

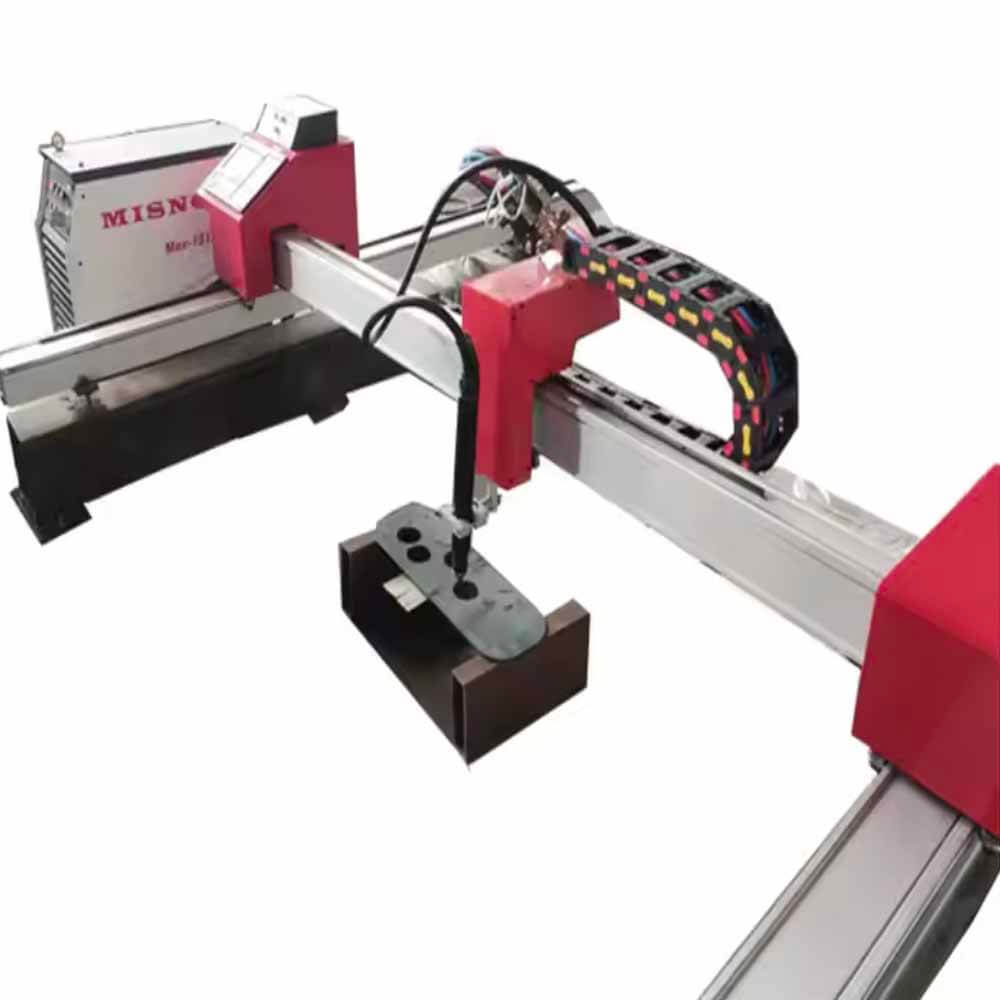

Advanced CNC Plasma Arc Cutting Machine Technology

A modern CNC plasma arc cutting machine comes equipped with features like automatic torch height control, nesting software, and digital control interfaces. These innovations help reduce material waste and increase cutting speed while maintaining excellent cut quality. Operators can program complex shapes with ease, resulting in consistent and repeatable results on every job.

Your Reliable CNC Plasma Cutting Machine Company in China

As a leading CNC plasma cutting machine company in China, we specialize in manufacturing and exporting cutting-edge equipment tailored to your specific industrial needs. Our machines are built using robust steel frames, premium plasma power sources, and user-friendly control systems.

What sets our CNC plasma cutting machine China offerings apart:

- Competitive factory-direct pricing

- Customizable table sizes and torch options

- Exceptional after-sales service and training support

- Rapid delivery and global shipping

- ISO and CE certifications

Whether you need a compact machine for workshop use or a large-format system for heavy-duty fabrication, we have the right solution for you.

CP-1560 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-2040 |

| Machine Type | Gantry CNC Plasma Cutting Machine |

| Working Area (X × Y) | 2000mm × 4000mm |

| Cutting Method | Plasma Cutting / Optional: Oxy-Fuel Cutting |

| Effective Cutting Area | 1500mm × 3000mm (Customizable upon request) |

| Plasma Power Source | Compatible with Huayuan / Hypertherm Power Supply |

| Cutting Thickness | Plasma: 1–25mm (depends on plasma power) Oxy-Fuel: 6–100mm |

| Cutting Speed | 0–8000mm/min (based on material and thickness) |

| Positioning Accuracy | ±0.2mm |

| Drive System | Dual-side stepper or servo motor drive |

| Transmission | Helical rack and pinion (X/Y axis), high-precision linear guide |

| Control System | STARFIRE / FLMC / START / FANUC CNC System |

| Software Compatibility | FastCAM, AutoCAD, CorelDRAW (G-code Support) |

| Gas Type (for Oxy-Fuel) | Oxygen, Acetylene / Propane |

| Working Voltage | AC380V, 50/60Hz, 3 Phase |

| Table Type | Blade Table / Water Table (optional) |

| Dust Collection | Smoke and dust removal system optional |

| Machine Weight | Approx. 1800–2500kg (varies based on configuration) |

| Optional Features | Drilling Head, Rotary Axis for Pipe Cutting, Auto Height Controller (THC), Flame Torch |

Conclusion

Investing in a reliable CNC plasma and oxy fuel cutting machine ensures precision cutting, improved efficiency, and long-term value. Partner with a trusted CNC plasma cutting machine company in China and take your metalworking operations to the next level. Contact us today to get a quote or learn more about our complete product lineup.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution