CNC Plasma Cutting Machine for Square and Round Metal Tubes

- Model: CP-R200

- Working Size: 50*2000mm

- Plasma Source: 120A (Optional 63/100/160/200/300/400A)

- Cutting Thickness: 1-20mm

- Availability: Production after order confirmation (Preorder)

- Payment Method: Bank Transfer (T/T), Trade Assurance

- Standard - Meeting CE Standards in Terms of Quality & Safety

- Warranting - One (1) Year Limited Warranty for Entire Machine

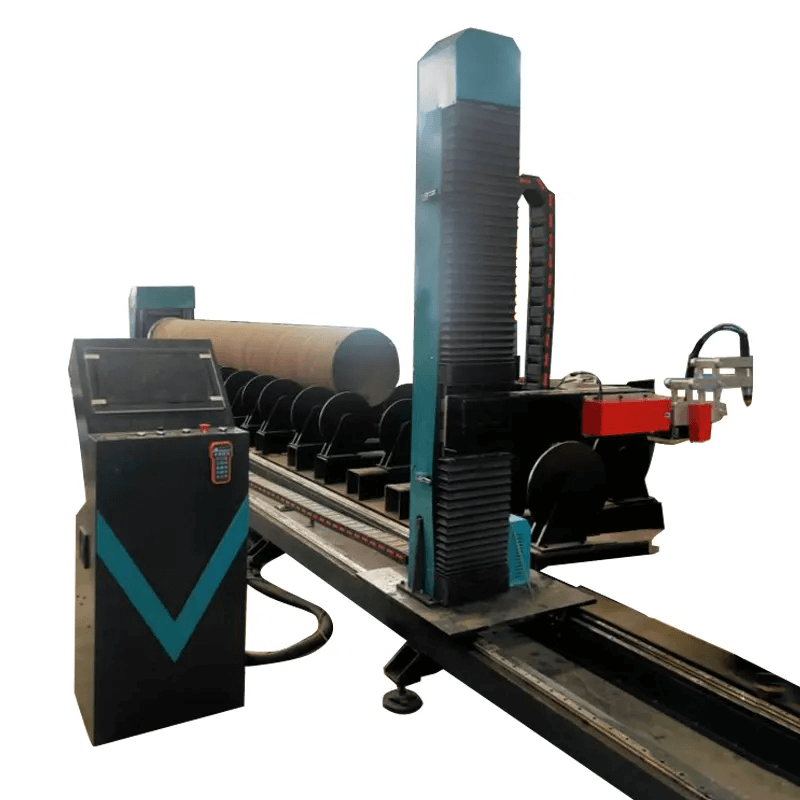

The CNC Plasma Cutting Machine for square and round metal tubes is a versatile and precise solution designed to meet the demands of modern metal fabrication. Equipped with advanced CNC control and rotary cutting capabilities, it efficiently handles various metal tubes, including carbon steel, stainless steel, and aluminum. This machine excels at cutting complex shapes, bevels, and holes with high accuracy, making it ideal for industries such as construction, automotive, shipbuilding, and mechanical engineering. Its robust design and automated features ensure smooth operation, enhanced productivity, and superior cut quality.

Features of CNC Plasma Cutting Machine for Square and Round Metal Tubes

- Roller Bed Support System — Equipped with multiple rollers that provide stable and smooth rotation of large diameter pipes, ensuring precise positioning during cutting.

- Heavy-Duty Design — Built to handle the weight and size of large steel pipes, with a robust structure to support heavy workloads.

- Advanced CNC Control — Utilizes a computer numerical control system to accurately guide the plasma or oxy-fuel cutting torch for highly precise and repeatable cuts.

- High Cutting Capacity — Designed specifically for cutting and beveling pipes with large diameters, offering a wider working area and deeper cutting capability than standard CNC plasma cutters.

- Versatile Cutting Methods — Supports both plasma cutting for fast and clean cuts and oxy-fuel cutting for thicker pipe sections and beveling tasks.

- Smooth Pipe Rotation — The roller bed enables seamless rotation of the pipe, allowing complex 3D cutting patterns and bevels with consistent accuracy.

- User-Friendly Interface — Integrated control panel and software simplify operation, programming, and monitoring of cutting processes.

- Improved Efficiency and Accuracy — Automatic positioning and controlled cutting parameters reduce waste, enhance cut quality, and boost production throughput.

Specification of CNC Plasma Cutting Machine for Square and Round Metal Tubes

| Parameter | Details |

|---|---|

| Pipe Diameter Range | 50 mm to 2000 mm |

| Pipe Length Options | 3 meters, 6 meters, 9 meters, 12 meters |

| Cutting Method | Plasma cutting (Oxy-fuel cutting optional) |

| Cutting Speed Range | 10 to 3500 mm/min |

| Rotation Speed | Up to 8 RPM |

| Drive System | Servo motor driven |

| A-Axis Bevel Angle | ±60 degrees |

| B-Axis Bevel Angle | ±45 degrees |

| Cutting Thickness | Depends on plasma source power and material |

| Power Supply Voltage | 380V ±10% |

| Operating Environment | Temperature: -10°C to 50°C |

| Humidity: ≤ 80% (non-condensing) | |

| Control System | Advanced CNC controller with user-friendly interface |

| Torch Height Control | Automatic THC (Torch Height Control) |

| Material Compatibility | Carbon steel, stainless steel, aluminum, alloy steel |

| Precision Positioning | ±0.1 mm accuracy in rotational and linear movement |

| Safety Features | Emergency stop, protective guards, fault alarms |

Application of CNC Plasma Cutting Machine for Square and Round Metal Tubes

The CNC Plasma Cutting Machine for large diameter round pipes is specifically engineered to handle heavy-duty cutting tasks on oversized metal pipes used in industries such as oil and gas pipeline construction, shipbuilding, power plants, industrial fabrication, and structural steel manufacturing. It efficiently processes thick-walled carbon steel, stainless steel, and alloy pipes with diameters ranging from medium to extra-large sizes.

Equipped with precise CNC control and rotary cutting functions, this machine delivers accurate cutting, beveling, and hole-making capabilities essential for pipe fitting, flange preparation, and complex joint fabrication. Its robust roller bed system supports smooth rotation and positioning of heavy pipes, enabling clean, precise cuts that improve welding efficiency and reduce material waste. Ideal for manufacturers requiring high productivity and superior cutting quality on large-scale pipe projects.