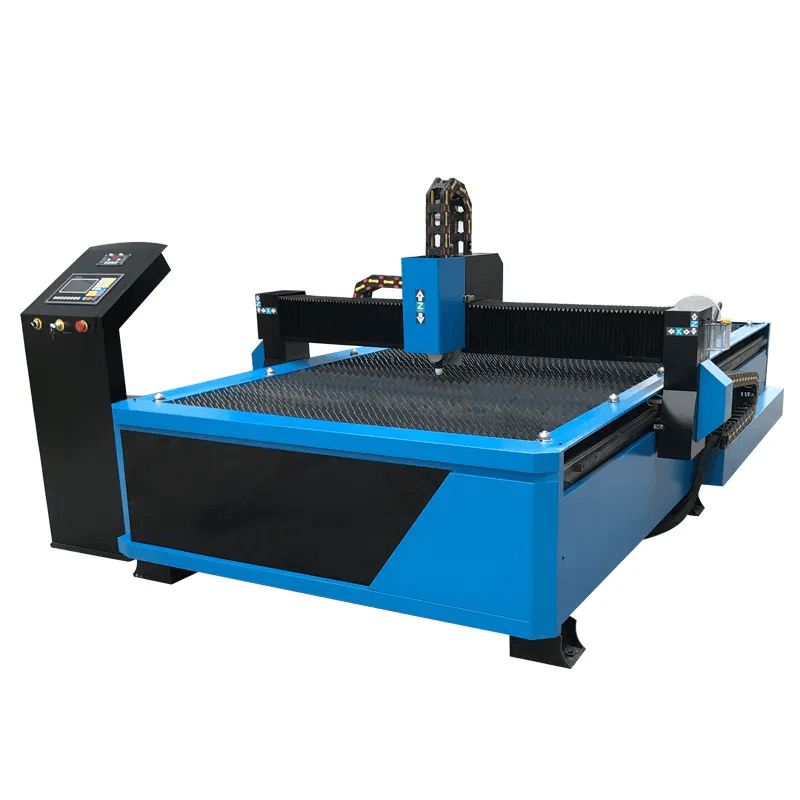

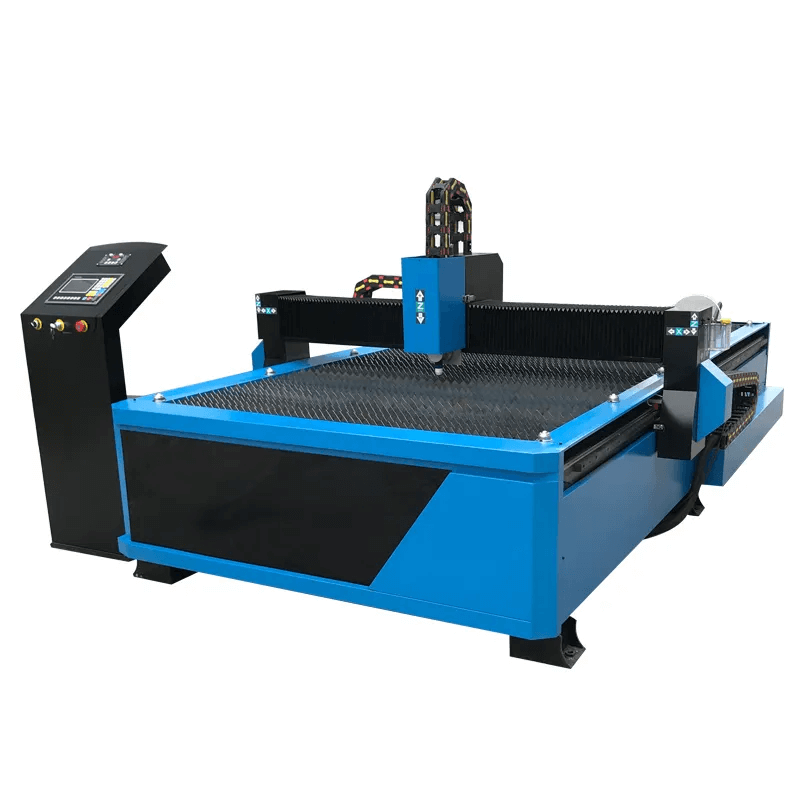

CNC Plasma Cutting Machine Parts, Prices & Programming Guide

Whether you’re setting up a new workshop or upgrading existing equipment, understanding the CNC plasma cutting machine parts, pricing, and programming is essential to make the right investment.

Table of Contents

Key CNC Plasma Cutting Machine Parts

A CNC plasma cutting machine is made up of several critical components that work together to deliver precision cutting. Here are the most important CNC plasma cutting machine parts you should know:

- Plasma Power Source: This is the heart of the machine, generating the plasma arc. Popular brands include Hypertherm and Huayuan.

- CNC Controller: The brain of the system, it interprets G-code to control movement and torch operation. Common systems include Starfire, Start CNC, and FLMC.

- Torch & Torch Height Controller (THC): Maintains the ideal distance between the torch and material, ensuring quality cuts and extending torch life.

- Drive Motors: Stepper or servo motors drive the machine along X, Y, and Z axes for accurate motion control.

- Linear Guides and Rack & Pinion System: Ensure smooth and precise movement of the cutting head.

- Cutting Table: May include a blade table or water bed to support the workpiece and reduce sparks or smoke.

- Cabinet & Wiring: Houses electrical components and protects the system from damage.

- Cooling System: Typically air-cooled, though water cooling may be used for higher-power systems.

Understanding each part’s function helps you maintain the machine better and source replacement components efficiently when needed.

CNC Plasma Cutting Machine Prices: What Affects the Cost?

CNC plasma cutting machine prices can vary widely depending on several factors:

- Working Size: Larger machines (e.g., 1500x6000mm) cost more than smaller table-top models.

- Power Source: Machines equipped with high-amperage or branded plasma sources (like Hypertherm) are more expensive.

- Control System: Advanced systems with better precision and user-friendly interfaces increase overall cost.

- Automation Level: Features like automatic THC, servo motors, and nesting software add to the price.

- Add-Ons: Options like oxy-fuel torches, rotary axes, and fume extractors raise the machine’s value.

- Brand and Country of Origin: Chinese manufacturers typically offer more competitive prices, while Western brands may be higher in cost.

Entry-level machines may start from $3,000–$5,000, while industrial-grade systems with all advanced features can exceed $20,000.

CNC Plasma Cutting Machine Programming: How It Works

CNC plasma cutting machine programming is essential for accurate and automated cutting. It involves converting a digital design (usually a DXF or DWG file) into machine-readable G-code, which controls the torch path, speed, and other parameters.

Here’s a basic overview of the programming process:

- Design Creation: Use CAD software like AutoCAD or SolidWorks to create your part or layout.

- CAM Processing: Import the design into CAM software (like FastCAM, StarCAM, or SheetCAM) to generate toolpaths and cutting parameters.

- G-Code Output: The CAM software produces G-code, the language understood by the CNC controller.

- Machine Upload: Load the G-code file into the CNC control system using USB or network transfer.

- Cutting Execution: Run the program, and the machine cuts the material based on the programmed instructions.

Proper programming ensures minimal material waste, precise part dimensions, and reduced operator errors.

CP-1530 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-1530 Table CNC Plasma Cutter |

| Working Area | 1500mm x 3000mm |

| Cutting Mode | Plasma Cutting (Optional: Flame Cutting) |

| Plasma Power Source | Optional (e.g., Huayuan, Hypertherm, LGK) |

| Plasma Cutting Thickness | 0.5mm – 25mm (Depending on power source) |

| Cutting Speed | 0–8000mm/min (varies by material and thickness) |

| Travel Speed | 0–12000mm/min |

| Control System | STARFIRE / FLMC-F2300A / START / Optional Brands |

| Software Compatibility | FastCAM, AutoCAD, ArtCAM, Type3, etc. |

| Drive System | Stepper or Servo Motors (optional) |

| Transmission System | X, Y Gear Rack; Z Ball Screw |

| Guide Rail Type | Linear Guide Rail (Hiwin/Taiwan square rail) |

| Working Table Type | Blade Table with Slag Drawer |

| Positioning Accuracy | ±0.05mm |

| Repositioning Accuracy | ±0.03mm |

| Working Voltage | 380V/220V, 3 Phase, 50/60Hz |

| Cooling Mode | Air-cooled or water mist cooling (optional) |

| Gas Supply | Compressed Air / Oxygen / Acetylene / Propane |

| Nesting Software | FastCAM Standard / Optional Nesting Software |

| Optional Functions | THC (Torch Height Controller), Auto Ignition, Rotary Axis, Dust Cover |

| Machine Dimensions | Approx. 2100mm x 3500mm x 1500mm |

| Machine Weight | Approx. 1000–1500kg |

Conclusion

Investing in a CNC plasma cutter is a smart move for modern metal fabrication. By understanding the CNC plasma cutting machine parts, evaluating the prices, and mastering the programming process, you’ll be better prepared to choose the right machine and use it effectively.

Whether you’re buying your first CNC machine or expanding your workshop, always work with a trusted supplier who can offer technical support, training, and high-quality components.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution