CNC Plasma Industrial Machines and Plasma Cutting Tables

Coupled with a reliable plasma cutting table, these machines enable businesses to meet demanding production goals with ease.

Table of Contents

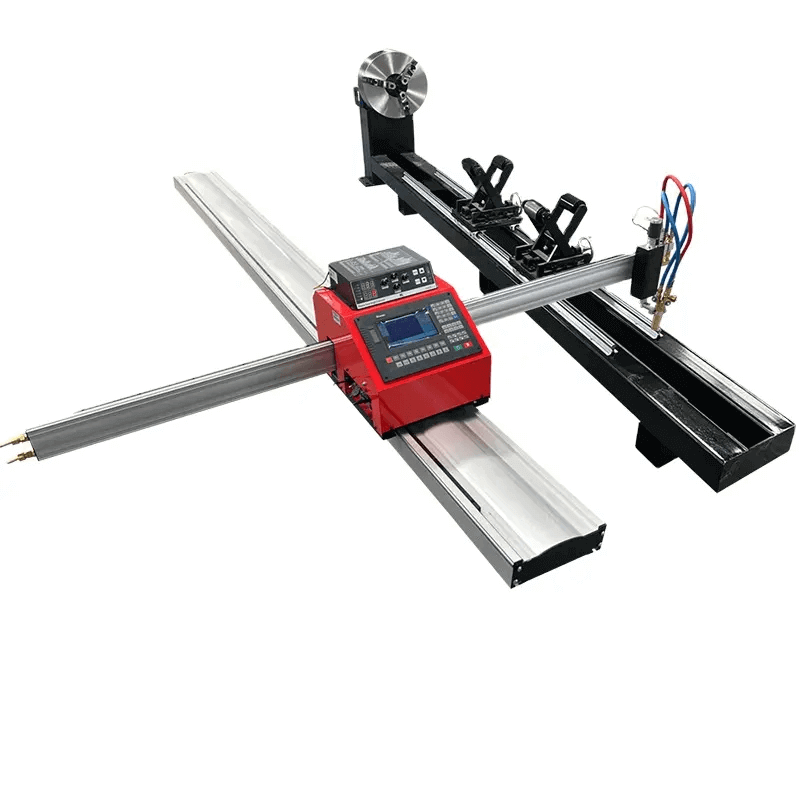

What Is a CNC Plasma Industrial Machine?

A CNC plasma industrial machine integrates plasma cutting technology with computer numerical control (CNC) to automate the metal cutting process. This combination allows for consistent, high-quality cuts on various metals, including steel, aluminum, and stainless steel. Industrial-grade plasma machines are built to withstand heavy use in manufacturing and fabrication environments.

The Role of a Plasma Cutting Table

The plasma cutting table is a sturdy platform designed to support metal sheets during cutting. It ensures stability and precise positioning of the workpiece, which is critical for achieving clean, accurate cuts. Advanced tables often feature adjustable slats, water beds, or fume extraction systems to enhance cutting quality and workplace safety.

Specialized Cutting: Pipe Cut Plasma

For industries dealing with tubular materials, pipe cut plasma technology offers specialized cutting capabilities. This feature allows for precise, clean cuts on pipes and cylindrical components, essential in sectors like construction, automotive, and shipbuilding.

CP-1540 Table CNC Plasma Cutting Machine Specification

| Specification Item | Details |

|---|---|

| Model | CP-1560 CNC Plasma Cutting Machine |

| Working Area | 1500 mm × 6000 mm (5 ft × 20 ft) |

| Cutting Thickness | 1 mm – 40 mm (depends on plasma source) |

| Positioning Accuracy | ±0.01 mm |

| Repeat Positioning Accuracy | ±0.005 mm |

| Maximum Cutting Speed | 0 – 12,000 mm/min |

| Drive System | Stepper motors / Servo motors (optional) |

| Control System | DSP or CNC controller compatible with Mach3, Starcam, etc. |

| Plasma Power Supply | Optional, typically 80A to 200A plasma source |

| Cutting Gas | Air, Oxygen, Nitrogen (depending on material) |

| Table Structure | Heavy-duty welded steel frame |

| Torch Type | Automatic torch height control supported |

| Software Compatibility | AutoCAD, CorelDraw, CAD/CAM |

| Interface | USB / Ethernet |

| Voltage | 220 V / 380 V (Optional) |

| Cooling System | Air-cooled or water-cooled (depends on plasma source) |

| Machine Weight | Approx. 2500 – 3000 kg |

| Machine Dimensions | Approx. 8000 mm × 2500 mm × 1500 mm |

| Optional Accessories | Water table, flame cutting torch, dust collector, rotary axis |

Why Choose a CNC Plasma Table?

A CNC plasma table combines the automation of CNC systems with plasma cutting precision. This synergy offers:

- High-speed cutting with minimal operator intervention

- Ability to cut complex shapes and designs accurately

- Reduced material waste through precise control

- Compatibility with various CAD/CAM software for seamless workflow integration

Understanding Plasma Cutting Machine Price

The plasma cutting machine price varies based on power output, cutting area size, CNC controller sophistication, and additional features like automatic torch height control or water cooling. Investing in a quality plasma machine ensures durability, better cut quality, and lower maintenance costs in the long run.

Conclusion

A CNC plasma industrial machine paired with a high-quality plasma cutting table is a game-changer for metal fabrication industries. Whether you require pipe cut plasma functionality or large-scale cutting capabilities, understanding your needs and budget will help you select the ideal plasma cutting solution at the right plasma cutting machine price.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution