High-Performance CNC Plasma Cutting Machines for Metal

Whether you need a gantry-style plasma CNC cutting machine for large-scale projects or a portable CNC plasma cutter for on-site tasks, cnc plasma cutting machine factory offers the right solution.

Table of Contents

Why Choose a CNC Plasma Cutting Machine?

A CNC plasma cutting machine uses high-temperature ionized gas (plasma) to melt and cut through metal. Controlled by computer software, it ensures accurate and repeatable cuts for both thin and thick metal sheets.

Benefits include:

- High cutting speed and accuracy

- Lower operational costs compared to laser cutting

- Suitable for complex shapes and detailed designs

- Compatible with various metals including mild steel, stainless steel, and aluminum

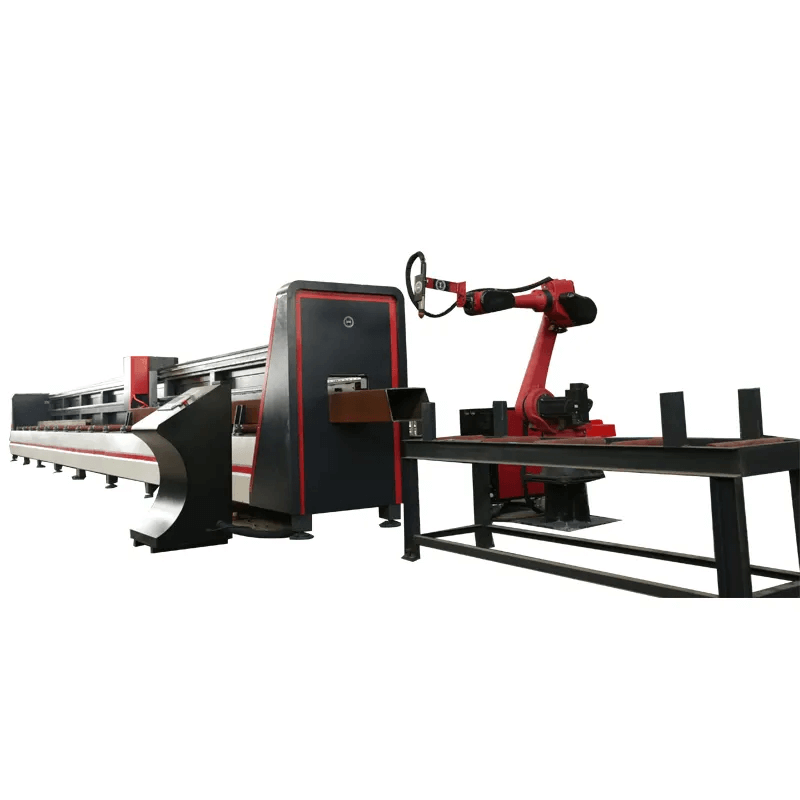

Our Featured CNC Plasma Cutting Machines

we provide machines tailored to your business needs.

Gantry CNC Plasma Cutting Machines

- Ideal for heavy-duty sheet metal fabrication

- Strong and stable structure for large work areas

- Dual-drive system for smooth motion and high precision

Portable CNC Plasma Cutters

- Lightweight and space-saving design

- Perfect for workshops and small businesses

- Easy to move and operate on-site

Flame + Plasma Dual Function Models

- Integrated flame torch for cutting thick steel (>30mm)

- One machine, two capabilities—maximum flexibility

Applications of CNC Plasma Cutting Machines

Our machines are widely used in:

- Automotive parts manufacturing

- Metal signage and decoration

- Industrial equipment production

- Shipbuilding and aerospace components

- Construction steel cutting

CP-1530 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-Gantry Series (customizable: CP-1530G, CP-2040G, etc.) |

| Machine Type | Gantry Type CNC Plasma Cutting Machine |

| Cutting Area (X × Y) | 1500×3000 mm, 2000×4000 mm (customizable sizes) |

| Z-Axis Travel | 150 mm (optional height on request) |

| Cutting Speed | 0–8000 mm/min |

| Positioning Accuracy | ±0.05 mm |

| Repeatability | ±0.03 mm |

| Drive System | Dual-side servo motor drive (Stepper optional) |

| Control System | Starfire / Fangling F2100 / Hypertherm Controller |

| Plasma Power Source | LGK, Huayuan, Hypertherm (63A, 100A, 120A, 200A) |

| Cutting Thickness | 1–35 mm (depends on power source) |

| Cutting Mode | Plasma (Flame cutting optional) |

| Working Voltage | 3-phase 380V ±10%, 50/60Hz |

| Table Structure | Heavy-duty steel welded frame |

| Software Compatibility | FastCAM / StarCAM / AutoCAD (DXF, G-code supported) |

| Drive Motor | Leadshine / Panasonic / Yaskawa Servo Motor |

| Transmission System | Rack and pinion + linear guide rails |

| Cooling Method | Air-cooled / Water-cooled (optional) |

| Dust Removal System | Optional Exhaust Fan / Water Table |

| Machine Dimensions | Depending on model and working area |

| Gross Weight | Approx. 1200–2000 kg |

| Optional Features | Flame torch, Auto THC (torch height control), Nesting software, Rotary Axis |

What Affects CNC Plasma Cutting Machine Price?

The CNC plasma cutting machine price varies based on:

- Cutting size and working table dimensions

- Plasma power source (LGK, Hypertherm, etc.)

- Controller type (Starfire, Fangling, etc.)

- Additional features: flame cutting, fume extractor, water table, etc.

We offer both affordable models for startups and high-end systems for industrial use.

Conclusion

If you’re looking for a reliable and precise CNC plasma cutting machine for metal, you’ve come to the right place. From compact portable units to heavy-duty gantry machines, we have the perfect solution for your business. Browse our product range today and contact us for a free quote!

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution