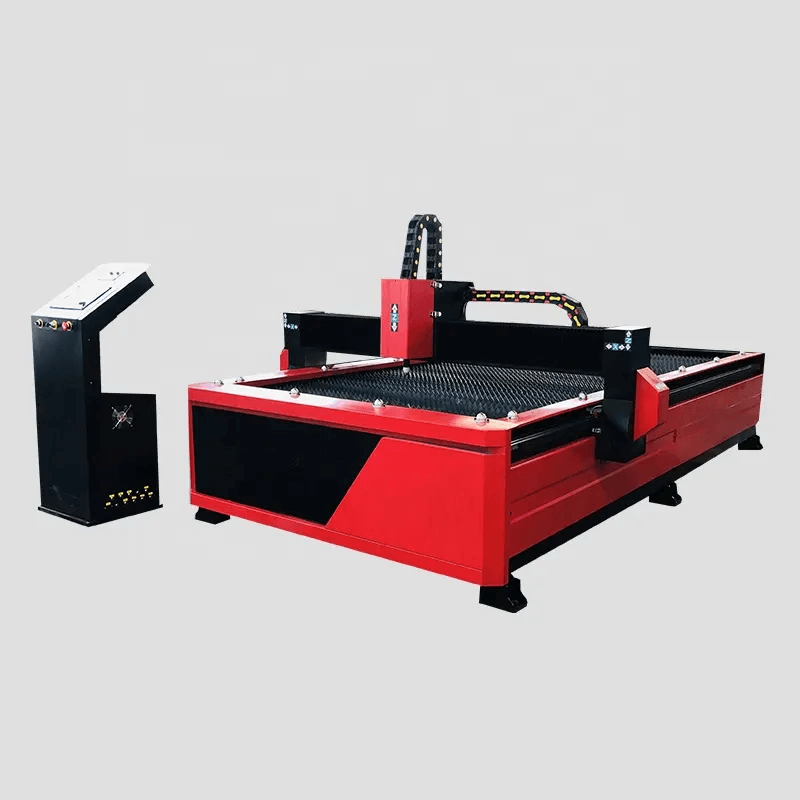

High-Precision CNC Plasma Cutting Machine and Table Kit

Whether you’re a fabrication shop owner, an industrial manufacturer, or a DIY enthusiast, investing in a plasma cutting table or a CNC plasma cutting machine can drastically improve your workflow, accuracy, and production speed.

Table of Contents

What Is a Plasma Cutting Machine?

A plasma cutting machine is a tool that uses a high-temperature plasma arc to cut through electrically conductive materials. It is commonly used for cutting metal plates, pipes, and structural components with high precision and minimal waste.

Types of Plasma Cutting Machines:

- Manual Plasma Cutters: Ideal for small-scale cutting and on-site work.

- CNC Plasma Cutting Machines: Equipped with computer-controlled automation for consistent and accurate cuts.

The Role of Plasma Cutting Tables

A plasma cutting table serves as the foundation for CNC plasma systems. It holds the metal material firmly while the CNC torch performs the cutting operation. These tables often feature:

- A grid or slatted surface to reduce back-spark and debris

- Water trays or downdraft systems to minimize smoke and fume

- X, Y, and Z axis movement for precise multi-dimensional cutting

When paired with a CNC plasma system, a quality cutting table ensures clean cuts, improved safety, and long-term machine durability.

CNC Plasma Kit: Customize Your Cutting Setup

For hobbyists and custom builders, a CNC plasma kit provides all the components needed to build or upgrade your plasma cutting system. A typical kit includes:

- Stepper or servo motors

- Controller boards

- Drive systems

- CNC software

- Torch height control (THC)

These kits are ideal for those looking to create a custom CNC plasma cutting machine tailored to specific workshop needs.

CP-1540 Table CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-1540 Table CNC Plasma Cutter |

| Working Area (X × Y) | 1500mm × 4000mm |

| Cutting Method | Plasma cutting (optional: flame cutting) |

| Table Type | Heavy-duty steel table with water bed / downdraft |

| Plasma Power Source | Optional: Hypertherm / Huayuan / LGK |

| Control System | STARFIRE / FLMC-F2300A / Start CNC |

| Drive System | Dual-side drive with precision stepper/servo motors |

| Transmission | X,Y: Rack and pinion; Z: Ball screw |

| Cutting Thickness | Depends on plasma power (e.g., 1–25mm typical) |

| Cutting Speed | 0–8000 mm/min |

| Positioning Accuracy | ±0.05 mm |

| Repeat Positioni |

Key Advantages of CNC Plasma Systems

- Speed & Efficiency: Cut through thick materials quickly

- Accuracy: Precision cutting reduces the need for secondary processing

- Versatility: Cut complex shapes and patterns in various materials

- Automation: Repeatable performance for mass production

Applications of Plasma Cutting Technology

- Industrial sheet metal processing

- Farm equipment repair and fabrication

- HVAC duct cutting

- Automotive chassis and bodywork

- Artistic metal signage and decor

Conclusion

The combination of a plasma cutting table and a CNC plasma machine provides unmatched flexibility and precision in modern fabrication. Whether you are building a custom solution with a CNC plasma kit or operating a high-end CNC plasma cutting machine, plasma cutting technology helps you meet today’s production challenges with efficiency and quality.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution