High-Precision CNC Plasma Pipe & Tube Cutting Machines | Hypertherm CNC Cutter

A CNC plasma pipe cutting machine or CNC plasma tube cutting machine offers the ideal solution for processing round, square, or rectangular pipes with accuracy and repeatability. When paired with a high-performance Hypertherm CNC plasma cutting machine, the result is unmatched cutting efficiency and smooth, clean edges every time.

Table of Contents

What is a CNC Plasma Pipe Cutting Machine?

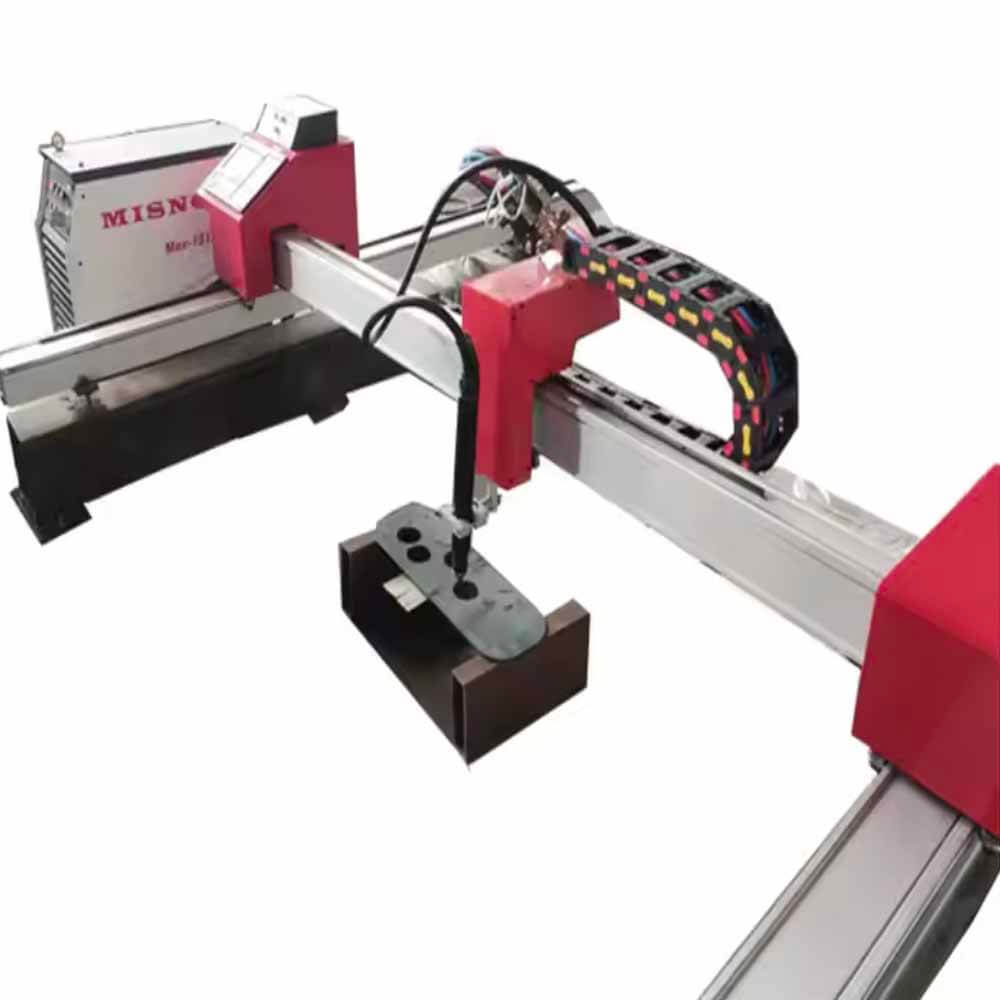

A CNC plasma pipe cutting machine is a computer-controlled cutting system designed to process cylindrical or square pipes using plasma cutting technology. It automates complex cutting tasks such as straight cuts, beveling, holes, saddle joints, and notches—reducing manual labor and minimizing waste. These machines are built to handle a wide range of pipe diameters and lengths, offering complete flexibility in manufacturing workflows.

CNC Plasma Tube Cutting Machine for Complex Profiles

Similar to pipe cutting machines, a CNC plasma tube cutting machine is tailored for cutting metal tubes, including square, round, and rectangular profiles. These machines are commonly used in architectural metalwork, automotive frames, and structural steel fabrication. Advanced models come with multi-axis rotation and nesting capabilities for optimal material usage.

Why Choose Hypertherm CNC Plasma Cutting Machine?

Hypertherm CNC plasma cutting machines are globally recognized for their superior arc quality, fast cutting speeds, and long consumable life. Integrating Hypertherm’s power supply, such as the Powermax or HPR series, into your pipe or tube cutting machine ensures:

- Cleaner Cuts: Minimal dross and smooth edges even on thick materials.

- Higher Productivity: Fast pierce and cut times reduce overall job duration.

- Lower Operating Costs: High efficiency and long consumable lifespan mean fewer replacements.

- Wide Material Compatibility: Cuts carbon steel, stainless steel, and aluminum with ease.

Key Features of a CNC Plasma Pipe/Tube Cutting System

- 360° Rotary Axis for multi-angle cuts and precision profiling

- Automatic Torch Height Control for consistent cutting depth

- CNC Controller with User-Friendly Interface

- Heavy-Duty Chuck System for stable pipe rotation

- Optional Bevel Cutting and Hole Piercing

- Compatible with Hypertherm, Huayuan, or other power sources

CP-1530 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CT-1530-TUBE |

| Machine Type | Portable CNC Plasma Cutter with Tube Cutting Function |

| Cutting Method | Plasma Cutting (Flame Cutting Optional) |

| Working Area (Plate) | 1500mm × 3000mm |

| Pipe Cutting Diameter Range | Ø30mm – Ø300mm (customizable) |

| Pipe Cutting Length | Up to 3000mm (optional extension available) |

| Pipe Material Types | Carbon Steel, Stainless Steel, Galvanized Pipe, Aluminum |

| Cutting Thickness (Plasma) | 1–25mm (depends on plasma power source) |

| Cutting Thickness (Flame) | 6–100mm (optional) |

| Cutting Speed | 0–8000 mm/min |

| Positioning Accuracy | ±0.3mm |

| Repositioning Accuracy | ±0.2mm |

| Drive System | Stepper Motor with Gear Rack Drive |

| Z-axis Control | Automatic Torch Height Controller (THC) |

| Control System | Starfire / Fangling / FLMC-F2300A (customizable) |

| File Format Supported | G Code / DXF via USB Transfer |

| Plasma Power Source | Optional: Huayuan / Hypertherm (45A/63A/100A/120A/200A) |

| Voltage Requirements | AC 220V / 380V, 50/60Hz |

| Software Compatibility | FASTCAM / StarCAM / AutoCAD |

| Machine Frame | Portable Gantry-Type with Detachable Pipe Chuck |

| Table Type (Plate Cutting) | Blade Table (optional water table) |

| Gas Type | Compressed Air / Oxygen / Mixed Gas |

| Torch Lifting Height | 150mm |

| Pipe Rotation | Manual or Motorized Chuck (custom option) |

| Optional Features | – Rotary Axis for Tube Cutting – Flame Cutting Torch – Bevel Cutting Attachment |

| Machine Weight | Approx. 650–850 kg |

| Overall Dimensions (L×W×H) | Approx. 2200 × 3500 × 1600 mm |

Conclusion

Whether you’re cutting round pipes for oil pipelines or square tubes for construction frameworks, investing in a CNC plasma pipe cutting machine or CNC plasma tube cutting machine will significantly improve your precision and productivity. By choosing a system equipped with a Hypertherm CNC plasma cutting machine, you get the benefit of trusted performance and superior cut quality. It’s a powerful combination that meets the demands of modern metalworking with speed, accuracy, and cost-effectiveness.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution