High Quality Plasma Cutter Solutions for Metal and Tube Cutting

A high quality plasma cutter offers all three—making it the preferred tool for professionals who demand clean cuts, minimal waste, and maximum productivity. Whether you’re cutting sheet metal or pipes, the right plasma cutter CNC system can make all the difference.

Table of Contents

Why Choose a High Quality Plasma Cutter?

When investing in a plasma cutter for metal, quality matters. A reliable machine offers:

- Smooth and accurate cuts

- Longer consumable life

- Stable performance

- Fewer downtimes

Whether you’re working with carbon steel, stainless steel, or aluminum, a high-quality machine ensures consistent results, even in demanding industrial environments.

CNC Plasma Cutter: Power Meets Precision

A plasma CNC cutter combines the raw cutting power of plasma with the precision of computer-controlled automation. These machines follow programmed designs to cut metal sheets into complex shapes with extreme accuracy. Ideal for mass production and custom jobs alike, CNC plasma cutters reduce labor costs and increase throughput.

Key benefits include:

- Automatic torch height control

- Software compatibility for design files (DXF, G-code)

- Fast travel speeds and efficient material usage

- Compatibility with various plasma power sources

Plasma Cutter for Metal: Sheet, Plate & Tube

If you need a plasma cutter for metal, it’s important to choose one based on the types of materials and shapes you’re working with:

- Flat sheet cutting: CNC plasma tables are ideal for cutting plates and sheets.

- Pipe and tube cutting: A CNC plasma tube cutter is designed specifically for round, square, or rectangular pipe cutting with high precision.

These tube cutters support bevel cuts, cope joints, and other complex geometries required in industries like HVAC, structural steel, and pipeline manufacturing.

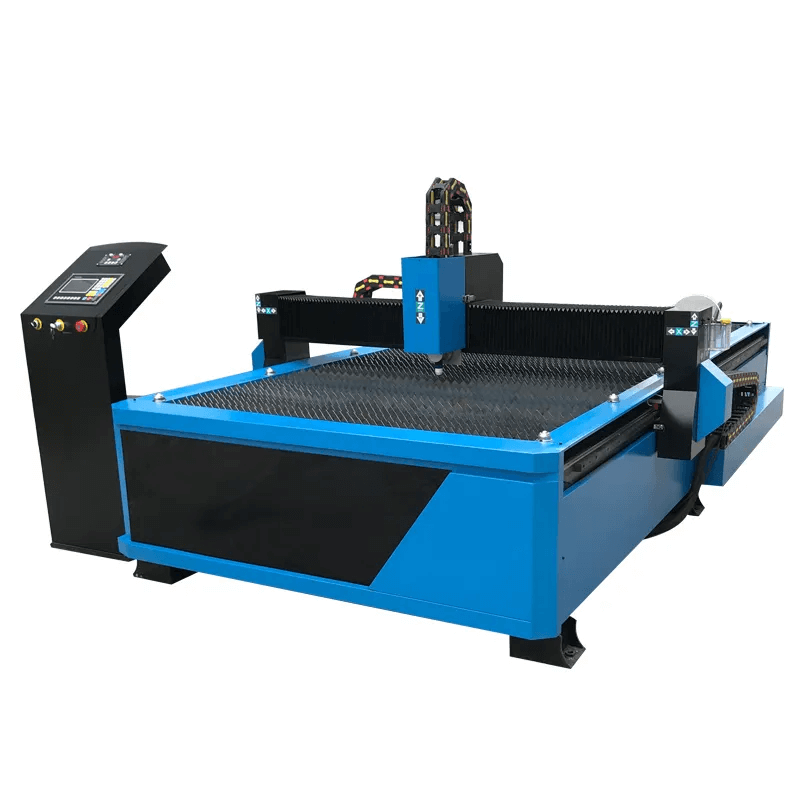

CP-1540 Table CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-TUBE200 / CP-TUBE300 (Customizable) |

| Cutting Pipe Type | Round Tube, Square Tube, Rectangular Tube |

| Round Pipe Diameter Range | 20 mm – 300 mm (customizable up to 500 mm) |

| Square/Rectangular Pipe Size | 20×20 mm – 200×200 mm |

| Max Pipe Length | 3,000 mm / 6,000 mm (standard); optional extension available |

| Plasma Power Source | Huayuan / LGK / Hypertherm (63A / 100A / 120A / 160A / 200A optional) |

| Cutting Thickness | 1 mm – 25 mm (depending on plasma power source) |

| Control System | STARFIRE / FLMC-F2300 / Shanghai Fangling |

| Drive System | Stepper motor or Servo motor (optional upgrade) |

| Cutting Accuracy | ±0.3 mm |

| Rotary Axis | Pneumatic or chuck-type rotating fixture |

| Clamping Method | Manual / Pneumatic Chuck (optional electric chuck) |

| Software Compatibility | FASTCAM, AutoCAD, G-code, .nc, .txt files |

| Working Voltage | AC220V / AC380V, 50/60Hz |

| Cooling Method | Air cooling (water cooling optional) |

| Torch Height Control | Automatic THC (torch height controller) |

| Working Environment | 0–45°C, non-condensing humidity |

| Optional Functions | Marking, Drilling, Bevel Cutting |

| Warranty | 1 year on machine, lifetime technical support |

Portable and Industrial Options

Plasma CNC cutters come in various configurations—from compact, portable systems for on-site repairs to large-format industrial machines for high-volume fabrication.

- Portable CNC plasma cutters: Ideal for workshops, farms, or small fabrication businesses.

- Industrial CNC systems: Suitable for heavy-duty operations in shipyards, automotive plants, and metalworking factories.

Choosing the Right CNC Plasma Cutter

When selecting a CNC plasma cutter, consider:

- Cutting thickness requirements

- Table size and space availability

- Software and controller options

- Plasma power source brand and capacity

- Support and maintenance availability

Conclusion

A high quality plasma cutter is a valuable investment for any metalworking business. Whether you need a plasma cutter CNC for flat sheets or a CNC plasma tube cutter for pipe work, choosing the right machine ensures better results, faster job completion, and long-term reliability.

Explore our full range of plasma CNC cutters and take your metal fabrication capabilities to the next level.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution