Mini CNC Plasma Cutter Table: Efficient Cutting Solutions for Small Workshops

Alongside single arm CNC plasma cutters and plasma flame cutting machines, these tools enable metal fabrication businesses to improve productivity and deliver high-quality cuts on steel, aluminum, and other metals.

Table of Contents

What Is a Mini CNC Plasma Cutter Table?

A mini CNC plasma cutter table is a compact CNC cutting system designed for small-scale metalworking operations. Despite its size, it delivers high precision, fast cutting speeds, and smooth edges, making it ideal for workshops with limited space.

Key Features:

- Compact and portable design

- High precision with CNC-controlled movement

- Suitable for steel, aluminum, brass, and other metals

- User-friendly interface for easy operation

Applications: Small workshops, custom metal parts fabrication, signage, and DIY metal projects.

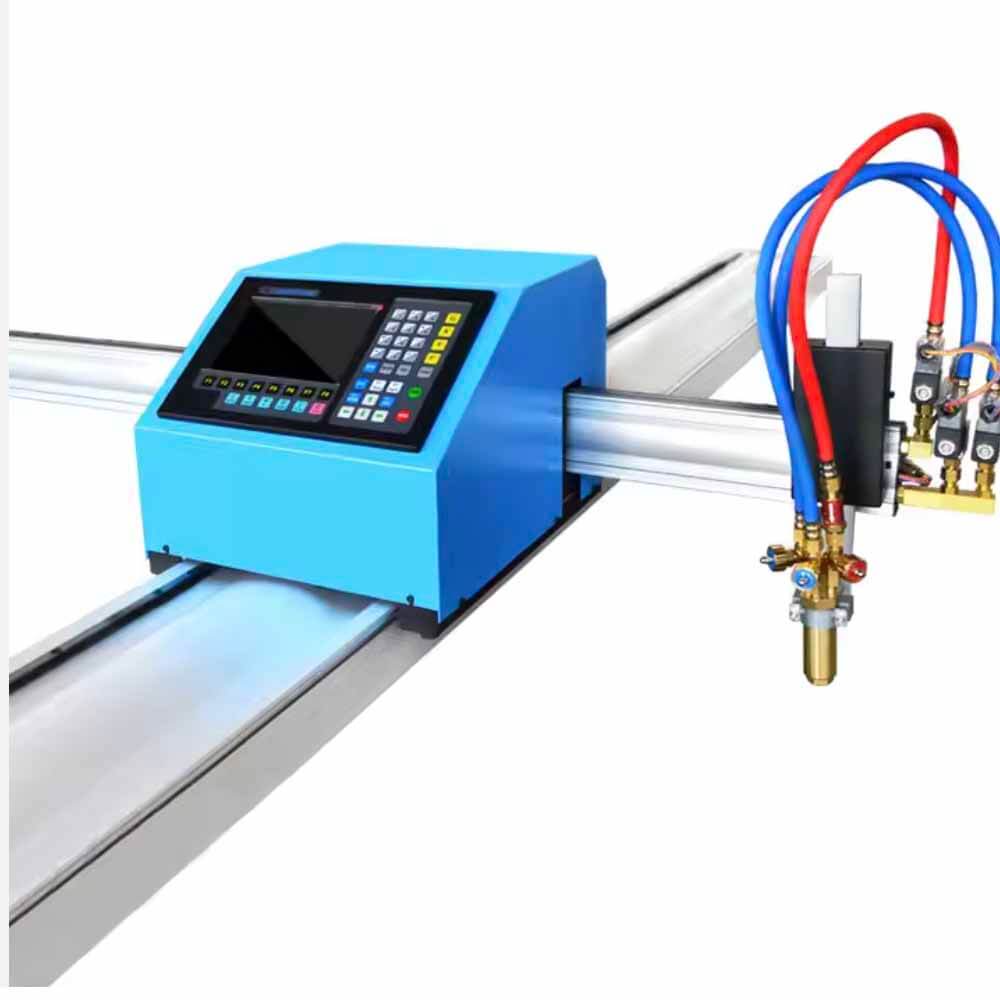

Single Arm CNC Plasma Cutter: Flexible and Efficient

A single arm CNC plasma cutter is a versatile machine used for both industrial and custom cutting applications. Its single-arm design allows for flexibility in cutting shapes and angles while maintaining stability and accuracy.

Advantages:

- Flexible arm movement for various cutting patterns

- Compatible with plasma cutting torches and flame cutting heads

- Reduces labor costs by automating complex cuts

- Ideal for small to medium-sized production batches

Applications: Sheet metal cutting, automotive parts, industrial fabrication, and custom metal projects.

CP-1530 CNC Plasma Cutter – Specification

| Item | Specification |

|---|---|

| Model | CP-1530 |

| Machine Type | Table CNC Plasma Cutting Machine |

| Working Area (X × Y) | 1500 × 3000 mm |

| Cutting Thickness | 1–30 mm (depends on plasma power source) |

| Plasma Power Source | 63A / 100A / 120A / 160A / 200A (optional, brands like Huayuan or Hypertherm) |

| Cutting Speed | 0–8000 mm/min |

| Travel Speed | 0–12,000 mm/min |

| Control System | Starfire / Fangling / Start CNC Controller |

| Drive System | Stepper Motor / Servo Motor (Optional Upgrade) |

| Guide Rail | Precision Linear Guide Rail |

| Positioning Accuracy | ±0.02 mm |

| Repositioning Accuracy | ±0.03 mm |

| Table Type | Heavy-duty welded steel frame with water/optional dry table |

| Software Compatible | FastCAM, AutoCAD, Type3, CorelDraw (supports DXF/PLT formats) |

| Power Supply | 380V/50Hz (220V Optional) |

| Machine Weight | ~1200–1500 kg |

| Machine Dimension (L×W×H) | 3600 × 2200 × 1500 mm |

| Optional Features | – Flame cutting torch – THC (Torch Height Controller) – Dust extraction system – Water cooling bed |

Plasma Flame Cutting Machine: High-Power Metal Cutting

The plasma flame cutting machine combines plasma arc technology with flame cutting for thick metal plates. It delivers high-speed cutting while maintaining clean edges and reducing material waste.

Benefits:

- Capable of cutting thick metal plates up to several inches

- High-speed operation for industrial production

- Produces smooth and precise cuts with minimal burrs

- Can switch between plasma cutting and flame cutting for versatility

Applications: Shipbuilding, structural steel fabrication, heavy machinery parts, and industrial construction.

Why Choose CNC Plasma and Flame Cutting Machines?

- Precision: CNC control ensures accurate cuts for complex designs.

- Efficiency: Automated operation reduces manual labor and increases output.

- Versatility: Can cut various metals and thicknesses using plasma or flame technology.

- Cost Savings: Reduces waste and speeds up production time.

- Safety: Minimizes manual handling and exposure to sparks and heat.

Conclusion

Whether you are running a small workshop or an industrial fabrication plant, mini CNC plasma cutter tables, single arm CNC plasma cutters, and plasma flame cutting machines offer high precision, efficiency, and versatility. They streamline production, improve cutting quality, and reduce operational costs.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution