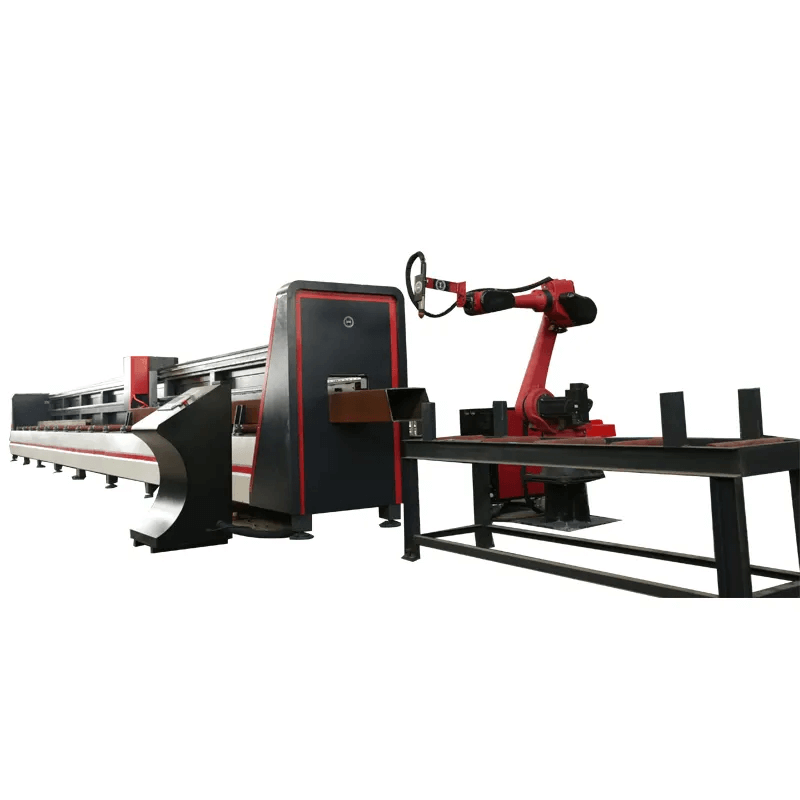

Robotic Plasma Cutting Machine with CNC Plasma Robotic Arm

A CNC plasma robotic arm combines the speed of plasma cutting with the agility of robotic motion, making it ideal for complex geometries, 3D contours, and large-scale production.

Table of Contents

What is a Robotic Plasma Cutting System?

A robotic plasma cutting system is an automated machine that uses a robotic plasma arm to move the torch along precise cutting paths. Controlled by CNC software, it can perform high-speed cuts on flat sheets, pipes, beams, and irregular shapes. This technology is widely used in shipbuilding, structural steel fabrication, and custom metalworking.

Key Features of CNC Plasma Robotic Arm Systems

High Precision Cutting

CNC-controlled movement ensures accurate dimensions.

Capable of cutting complex shapes and bevel edges.

Flexible Cutting Angles

Multi-axis robotic arm allows cutting in various directions and orientations.

Wide Material Compatibility

Suitable for carbon steel, stainless steel, aluminum, and galvanized steel.

High-Speed Productivity

Advanced plasma source for rapid cutting without compromising quality.

3D & Bevel Cutting Capability

Perfect for welding preparation and custom component manufacturing.

Applications of CNC Plasma Robotic Arm Technology

- Structural Steel & Construction

- Shipbuilding & Offshore Fabrication

- Aerospace & Automotive Components

- Industrial Machinery Manufacturing

- Custom Metal Art & Decorative Panels

Robotic Plasma Cutting Machine – Specifications

| Item | Specification |

|---|---|

| Machine Type | CNC Plasma Robotic Arm Cutting System |

| Axis Configuration | 6-Axis Robotic Arm + Optional Rotary Positioner |

| Cutting Range | Varies by robotic arm model (typ. reach 1400 – 3000 mm) |

| Cutting Thickness | 1 mm – 50 mm (depends on plasma source capacity) |

| Plasma Power Source | 100A / 200A / 300A (optional high-definition plasma) |

| Cutting Speed | 0 – 10,000 mm/min (adjustable) |

| Positioning Accuracy | ±0.3 mm |

| Repeatability | ±0.05 mm |

| Bevel Cutting Capability | ±45° multi-angle cutting |

| Material Compatibility | Carbon steel, stainless steel, aluminum, galvanized steel |

| Torch Type | Robotic plasma torch with automatic height control |

| Drive System | Servo motor drive with harmonic reducer |

| Control System | Industrial CNC robotic controller with 3D programming |

| Software Compatibility | Robot offline programming, DXF import, 3D nesting software |

| Rotation Device (Optional) | Rotary chuck for pipe & tube cutting (diameter up to 1500 mm) |

| Cooling System | Water cooling or air cooling (based on plasma source) |

| Dust & Fume Extraction | Integrated extraction hood or downdraft table |

| Power Supply | AC 380V ±10%, 50/60Hz, 3-phase |

| Overall Dimensions | Varies per robotic arm model & working cell layout |

| Net Weight | 2500 – 5000 kg (depending on configuration) |

| Safety Features | Emergency stop, collision detection, torch breakaway sensor |

| Optional Add-ons | Automatic loading/unloading, laser alignment, camera-based tracking |

Conclusion

The robotic plasma cutting system with CNC plasma robotic arm is the ultimate solution for modern fabrication needs. By integrating robotic flexibility with plasma cutting power, manufacturers can achieve unmatched speed, precision, and efficiency in their metalworking operations.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution