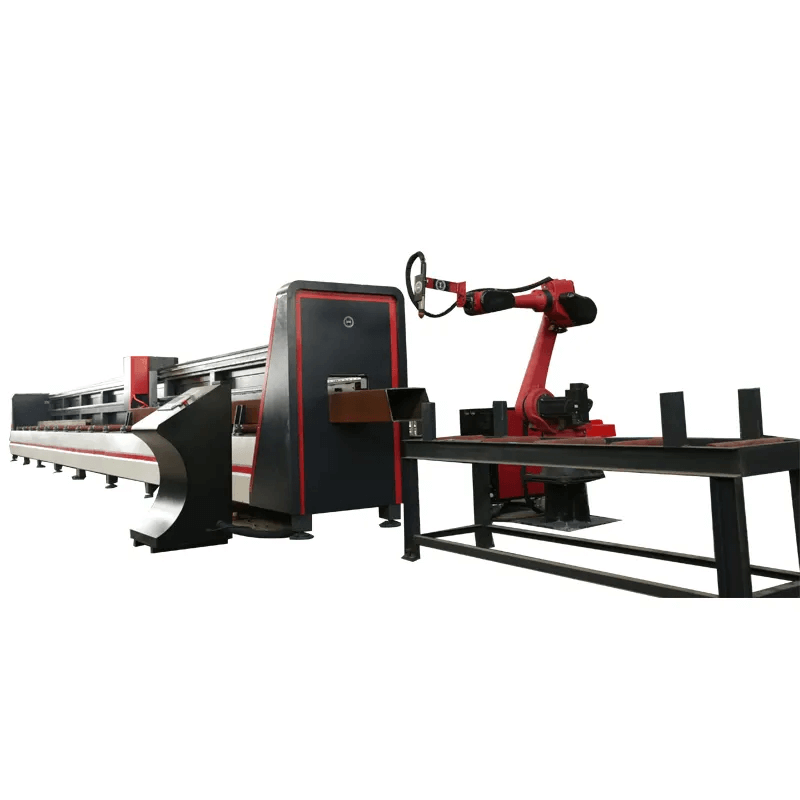

Robotic Plasma Cutting with CNC Plasma Robotic Arm

Combining the flexibility of a robotic arm with the power of plasma cutting, this system offers exceptional precision, speed, and automation. Whether you’re cutting sheet metal, pipes, or complex profiles, a CNC Plasma Robotic Arm delivers consistent, high-quality results while reducing production time and labor costs.

Table of Contents

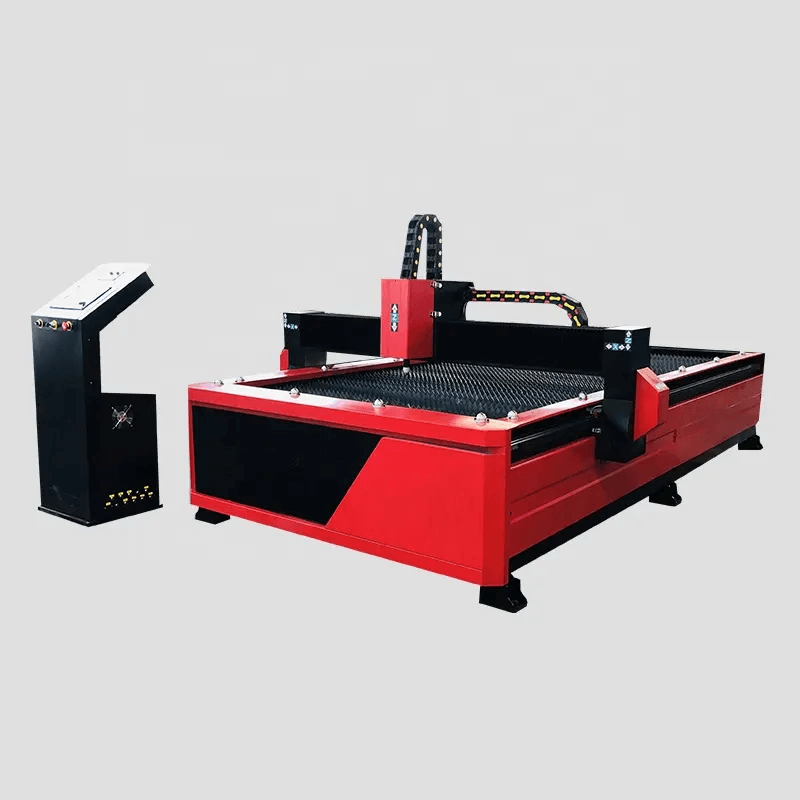

What is Robotic Plasma Cutting?

Robotic Plasma cutting is a process that uses a high-temperature plasma arc to cut through conductive metals, guided by a multi-axis robotic arm. Unlike traditional CNC plasma cutting tables, the CNC Plasma Robotic Arm can move freely in 3D space, making it ideal for complex geometries, angled cuts, and hard-to-reach areas.

Key Features of CNC Plasma Robotic Arm Systems

- Multi-Axis Flexibility – Perform complex cuts on various shapes and surfaces.

- High Cutting Speed – Significantly faster than manual cutting methods.

- Consistent Precision – Automated programming ensures accuracy in every cut.

- Wide Material Compatibility – Suitable for stainless steel, carbon steel, aluminum, and more.

- Reduced Waste – Optimized cutting paths minimize material loss.

- Improved Safety – Minimizes human exposure to high-temperature cutting areas.

Applications of Robotic Plasma Cutting

The versatility of CNC Plasma Robotic Arm systems makes them perfect for:

- Shipbuilding – Cutting large, curved steel plates with high accuracy.

- Automotive Industry – Processing chassis parts, frames, and body components.

- Structural Steel Fabrication – Cutting beams, tubes, and custom profiles.

- Aerospace – Creating precise parts from aluminum and titanium alloys.

- Heavy Machinery – Fabricating parts for mining, agriculture, and construction equipment.

Robotic Plasma Cutting Machine – Specifications

| Item | Specification |

|---|---|

| Model | CP-6AXIS-1530 |

| Type | CNC Plasma Robotic Arm |

| Axes | 6-Axis Articulated Robot |

| Working Envelope | Up to 3000mm reach |

| Load Capacity | 10–20 kg (Torch + Cables) |

| Cutting Method | Plasma Arc Cutting |

| Power Supply | 380V / 50Hz / 3 Phase |

| Plasma Source | Compatible with Hypertherm, Kjellberg, or custom plasma systems |

| Cutting Thickness | Mild Steel: up to 40mm (depends on plasma source) |

| Positioning Accuracy | ±0.05 mm |

| Cutting Speed | 0–10,000 mm/min (material dependent) |

| Control System | CNC Robotic Controller with Offline Programming |

| Drive System | Servo Motor Drive on All Axes |

| Cooling System | Air or Water Cooling (depending on plasma source) |

| Safety Features | Collision Detection, Emergency Stop, Overheat Protection |

| Applications | 3D shape cutting, pipe & tube cutting, bevel cutting, complex contour cutting |

| Optional Features | Rotating positioner, pipe cutting chuck, dust extraction system |

Advantages Over Traditional Plasma Cutting

When compared to fixed CNC plasma tables, Robotic Plasma Cutting offers:

- Greater Flexibility – Reach different angles and positions without repositioning the material.

- Compact Footprint – Takes up less floor space while offering more cutting possibilities.

- Higher Efficiency – Faster setup and automatic operation increase production rates.

- Future-Proof Technology – Easily adaptable to new designs and production needs.

Conclusion

If your business demands high precision, speed, and flexibility in metal cutting, investing in a Robotic Plasma Cutting Machine with a CNC Plasma Robotic Arm is a smart choice. It not only enhances productivity but also opens new possibilities in custom metal fabrication.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution