Unlocking the Power of CNC Flame/Plasma Cutting Machines

These advanced systems combine speed, accuracy, and versatility—making them a top choice for industries such as construction, shipbuilding, automotive, and metal fabrication.

Table of Contents

What is a CNC Flame/Plasma Cutting Machine?

A CNC flame/plasma cutting machine utilizes computer numerical control (CNC) to automate the process of cutting through various types of metal, including carbon steel, stainless steel, and aluminum. The machine can operate using plasma cutting, which employs a high-temperature ionized gas jet, or flame cutting, which uses an oxy-fuel torch for thicker and harder metals.

Many fabricators choose CNC plasma and flame cutting machines because of their dual capabilities—allowing them to switch between processes based on material thickness and precision requirements.

High Definition Cutting with CNC Plasma

For businesses demanding superior edge quality and tighter tolerances, the CNC high definition plasma cutting machine is the ideal solution. High-definition plasma systems produce cleaner cuts with less dross and narrower kerf widths, reducing the need for secondary processing. This makes it perfect for applications where finish and detail are crucial, such as signage, component parts, and decorative metalwork.

The Power of Laser and Plasma Combined

Innovative technology has also introduced the CNC laser plasma cutting machine, which integrates both laser and plasma systems in a single platform. This hybrid setup enables users to handle diverse materials and thicknesses with optimal efficiency. Plasma handles thicker sections quickly, while the laser offers extremely fine cuts on thin metal sheets. It’s a smart investment for shops needing flexibility in one machine.

Why Choose CNC Machine Plasma Cutting?

Using a CNC machine for plasma cutting brings several advantages:

- Automation reduces manual errors and increases repeatability

- Fast cutting speeds boost productivity and reduce turnaround time

- Precise control over cutting paths ensures high-quality outputs

- Compatibility with various nesting software improves material utilization

Whether you’re handling small batch jobs or high-volume production, CNC machine plasma cutting systems offer the performance and reliability required for modern fabrication needs.

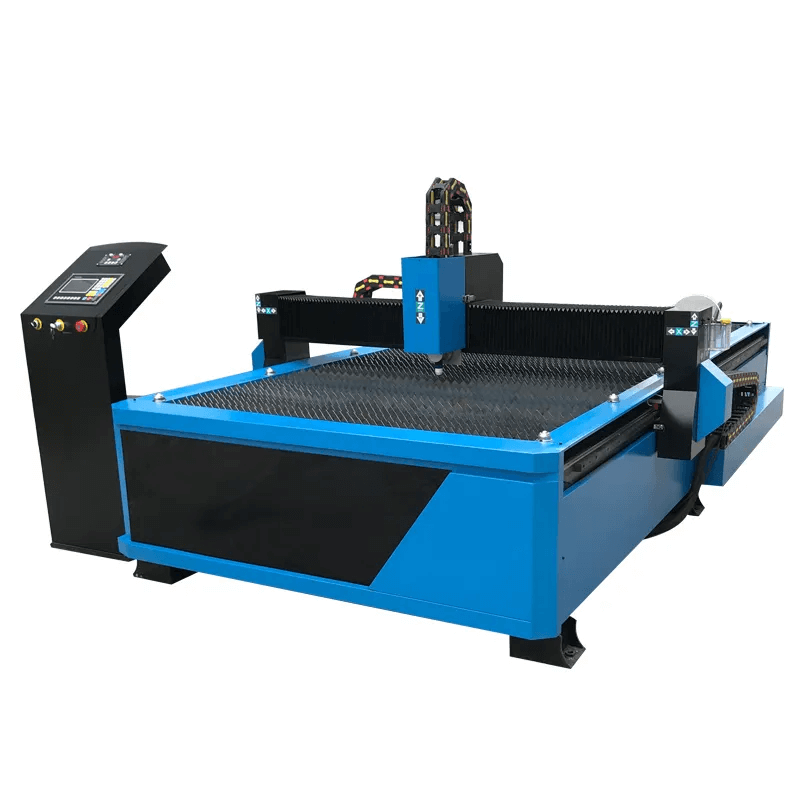

CP-1530 CNC Plasma Cutting Machine Specification

| Item | Specification |

|---|---|

| Model | CP-1325 CNC Plasma Cutting Machine |

| Working Area | 1300mm × 2500mm (X × Y axis) |

| Cutting Method | Plasma Cutting (Optional: Flame Cutting) |

| Plasma Power Source | 63A / 100A / 120A / 160A / 200A (Optional – Huayuan or Hypertherm) |

| Control System | Starfire / FLMC-F2300A (Optional upgrades available) |

| Drive Motor | Stepper Motor / Servo Motor (Optional by configuration) |

| Transmission System | Gear and Rack for X & Y Axis, Ball Screw for Z Axis |

| Cutting Thickness | 0.5mm – 25mm (Depending on plasma power source) |

| Cutting Speed | 0 – 8000 mm/min (Varies by material and power) |

| Positioning Accuracy | ±0.05mm |

| Repeat Positioning | ±0.03mm |

| Torch Height Control | Automatic THC (Torch Height Controller) |

| Table Type | Blade Table with Slag Collection Drawer |

| Control Software | FastCAM / StarCAM / ArtCAM (Supports G-code files) |

| Working Voltage | AC220V/380V ±10%, 50Hz/60Hz, 3 Phase |

| Supported Formats | G-code, DXF, NC |

| Cooling System | Air Cooling |

| Optional Features | Flame Torch, Rotary Axis, Water Table, Marking Head |

| Net Weight | Approx. 1200–1500kg (Varies with configuration) |

Conclusion

If you’re looking to upgrade your metal processing capabilities, a CNC plasma and flame cutting machine delivers unmatched performance across a wide range of applications. Whether it’s a CNC high definition plasma cutting machine for fine detail work or a CNC laser plasma cutting machine for dual-function flexibility, these systems offer the cutting-edge technology you need to stay ahead in today’s fast-paced market.

Leave a Comment

Products Categories

Recent News

WHY CHOOSE US

12+ years in precision CNC machining

22+ years of technical mastery in beverage automation

800+ installations across 100+ countries

10,000m² ISO-certified production plant

20+ global sales specialists for seamless client support

24/7 lifecycle services: maintenance, diagnostics, parts

FDA/CE-compliant quality design standards

Win-win partnerships prioritizing stakeholder growth

End-to-end solutions: Customized, Technicial, Solution